Worried about supply chain risk and disruption?

Why circular economy strategies are more resilient

4 minute read

The coronavirus is already highlighting supply chain risk and creating major headaches for many businesses. Yet again, the spotlight is shining on the fragility of our ever-more-complex global supply chains. Businesses large and small are discovering the downsides of their low-cost sourcing strategies: reliant on virgin resources and (often unclear) networks of overseas suppliers.

But what can you do to protect your business in the face of the next mega-disruption, whether driven by extreme weather, disasters, or even geo-politics?

In our first blog exploring Linear Risks, we explore how those businesses working towards a circular economy are mitigating these potentially fatal flaws. Their strategies include aiming to recover their own resources, to prioritise local supply and decentralised production, and to slow down consumption instead.

The coronavirus is spreading rapidly, and having a devastating effect on the lives of people in many countries. Our thoughts are with all those affected, around the world. As governments, healthcare professionals and the World Health Organization develop their response strategies, there are knock-on effects in the business world, too. We’re seeing lock-downs in affected cities, key professionals stranded overseas or in quarantine, cancelled flights and closure of many shops, tourist attractions and factories.

Supply chain directors all over the world are losing sleep over how to deal with serious operational disruptions. The virus outbreak was announced by NBC in the US on 21 January 2020. By the end of January, Forbes was reporting that ‘Apple’s supply chain is at risk from the Corona Virus’. This article from Forbes warns of the effects on Bosch, Honda, Hyundai, Nissan and others, and the impact on the wider economy.

Global supplier networks = more supply chain risk

Gartner posted an article responding to the effects of the pandemic and suggesting how to secure your supply chain. Gartner’s Koray Köse, Senior Director Analyst, says ‘The consequences of a pandemic event are hard to predict. […] However, the risks always exist and are augmented with further globalization and integration of supply chains.’

Gartner says it is difficult to predict the exact consequences: ‘organizations might begin to see impacts across the supply chain’, including shortages of materials and labour, travel and logistics disruptions, and even consumers being more cautious about their purchasing habits, and switching to online deliveries.

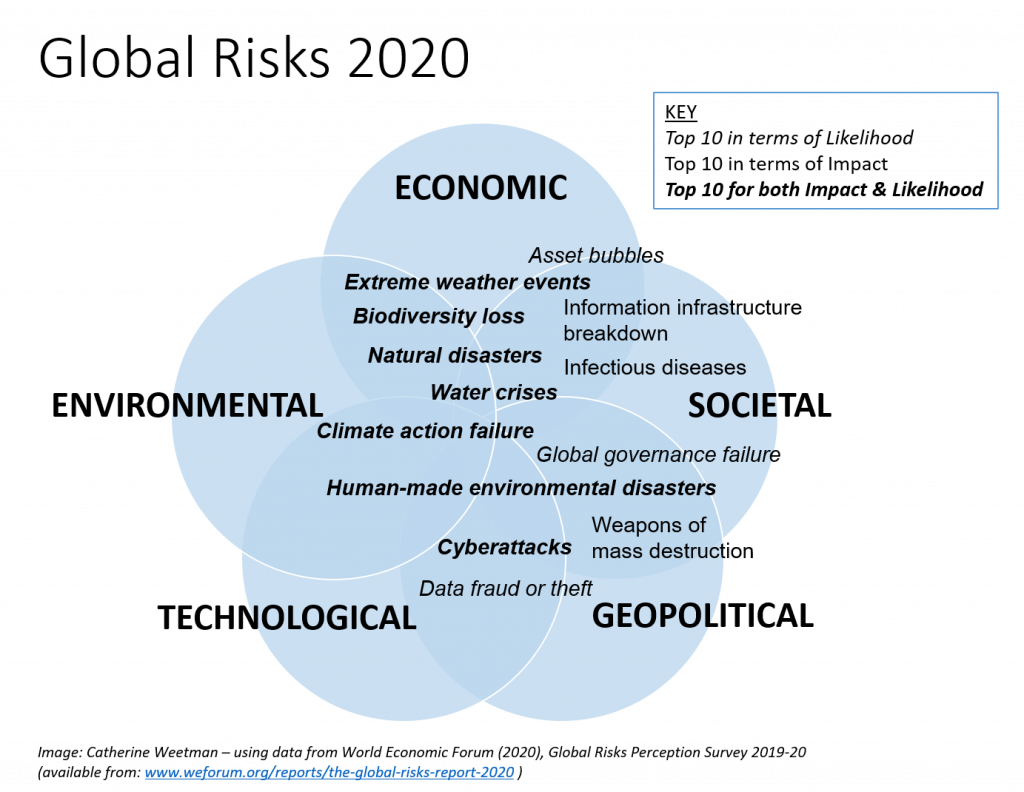

The 2020 update of the World Economic Forum (WEF) Risks Report, for the first time, ranks environmental risks in each of the top five ‘most likely’ slots. ‘Infectious diseases’, however, ranked at #10 for impact, but didn’t even make the top 10 for likelihood. Am I having a side-swipe at the WEF? No.

Using circular approaches to reduce supply chain risk

Instead, I want to highlight something more important. All the risks listed in the report’s top 10 – by likelihood or impact – affect supply chains. You can see this year’s top risks on my Venn diagram. Whether classed as Economic, Environmental, Geopolitical, Societal or Technical, they can disrupt ‘business as usual’ in one or many global regions. And that threatens the future of your business.

‘Hang on a minute’, you might be thinking. If even the WEF didn’t foresee a pandemic as a likely risk, who could blame me for not including it on my supply chain ‘risk radar’? Think about it this way: if you design your supply chain to prioritise resilience and agility, rather than cost and (apparent) simplicity, then you’d take a different approach to sourcing materials and selecting suppliers and sub-contractors.

Let me give you some examples. Many businesses rely on virgin, finite materials, often from less-than-transparent overseas sources. In contrast, in a circular economy, you’d use recycled materials instead. These could even come from your own recovered products, perhaps supplemented with production waste.

Maybe recovering and recycling your own raw materials sounds like a massive challenge. So why not collaborate with other players in your sector, or approach a recycling specialist? Look at the ‘ecosystem’ of organisations around your business – which ones could you link up with to improve your resilience? What win-win outcomes might there be?

“A leader is someone who steps back from the entire system and tries to build a more collaborative, more innovative system that will work over the long term.” Robert Reich, US Economist and Political Commentator

Slow the flow

You could reduce risk even further by extending the useful life of your products. How? By designing them to be easy to repair and upgrade, so your customers can keep using them for longer or resell them more easily – reducing their costs. On top of this, you could offer servicing and repairs, with new revenue streams coming from spare parts. Your happier customers will be giving you those valuable word-of-mouth recommendations too.

Another strategy is using modular designs, ideally with components specified across a range of your products. That makes it easier to have more than one supplier of each module – don’t forget to check that each tier of suppliers is unique, so you’re not ultimately reliant on (say) the same smelting mill or metal recycler.

There are further circular economy approaches to reduce linear risk and boost resilience and agility, including remanufacturing and reselling. There’s more on these circular economy strategies in our recent articles and blogs, including:

Don’t take risks you don’t understand

In Fault Lines: How Hidden Fractures Still Threaten the World Economy, Raghuram G. Rajan, former Chief Economist International Monetary Fund, reminds us that:

‘Not taking risks one doesn’t understand is often the best form of risk management.’

Let’s recap. Securing your own recycled or renewable materials and using local, decentralised manufacturing will help secure your supply chain in the face of future ‘unknown unknowns’. In addition, slowing down your consumption of resources by keeping your products in use for longer ‘decouples’ your revenue from resource consumption – and provides additional revenue streams.

Switch your radar on

Now go out there and switch your ‘risk radar’ on:

- What are you worried about?

- What hasn’t been on your radar, but should be?

- And what can you change so that it’s more circular, and reduces your supply-chain risk?

Good luck, and let us know if we can help.

Catherine Weetman advises businesses, gives workshops & talks, and writes about the circular economy. Her award-winning Circular Economy Handbook explains the concept and practicalities, in plain English. It includes a wide range of real examples and tips on getting started.

To find out more about the circular economy, why not listen to Episode 1 of the Circular Economy Podcast, read our guide: What is the Circular Economy, or stay in touch to get the latest episode and insights, straight to your inbox…