Why ‘semi-circular’ strategies are a sustainable step forward

You’re probably noticing the growing interest in the circular economy – but what on earth are ‘semi-circular’ strategies?

We unpack what podcast guest Steve Haskew meant by ‘semi-circular’ and look at why semi-circular strategies are a sustainable step in the right direction.

3 minute read

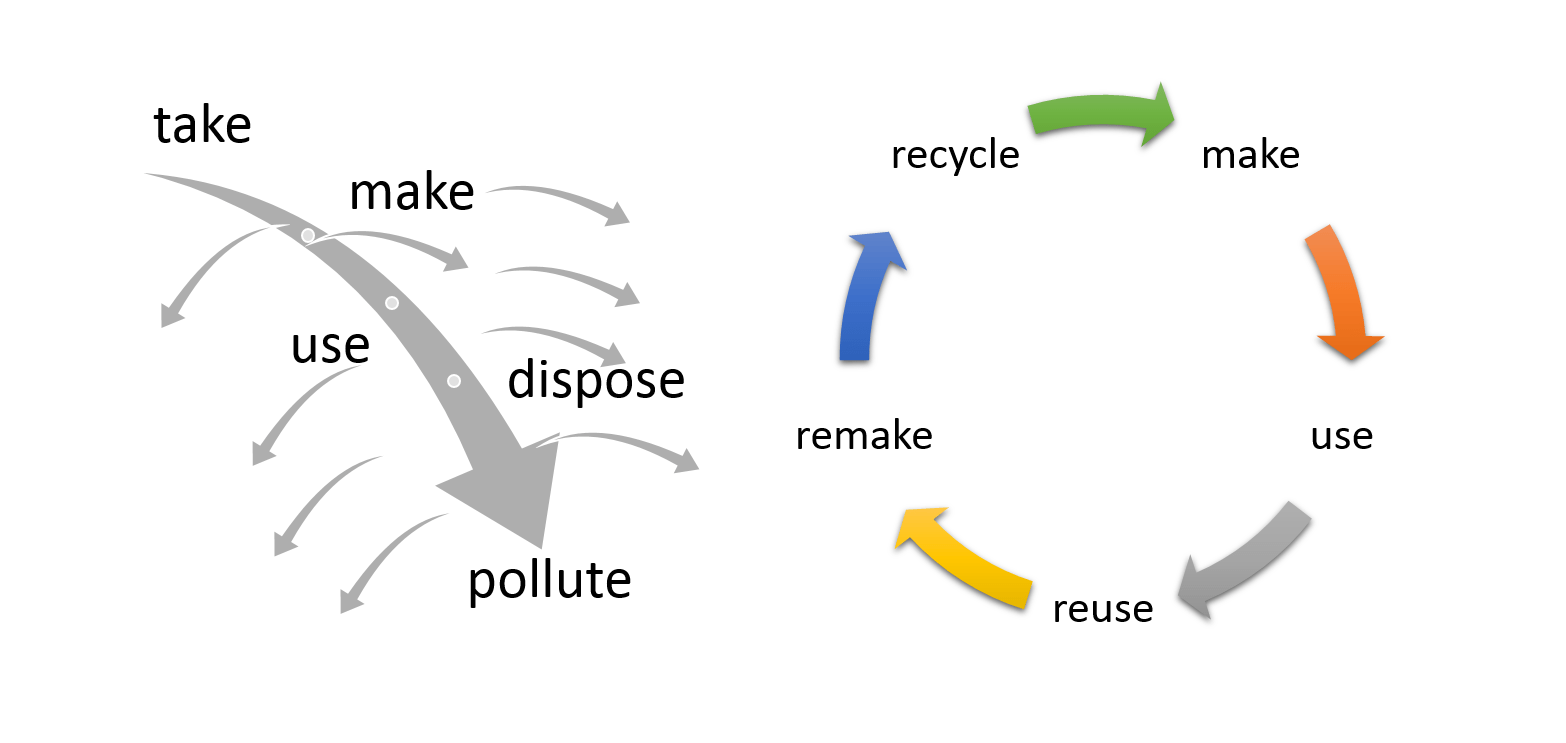

Sometimes, it feels like the circular economy concept is easier to understand than it is to implement. Is it ok just to make a product or business more circular than it was? Or are we missing the point… and even risking #circularwashing?

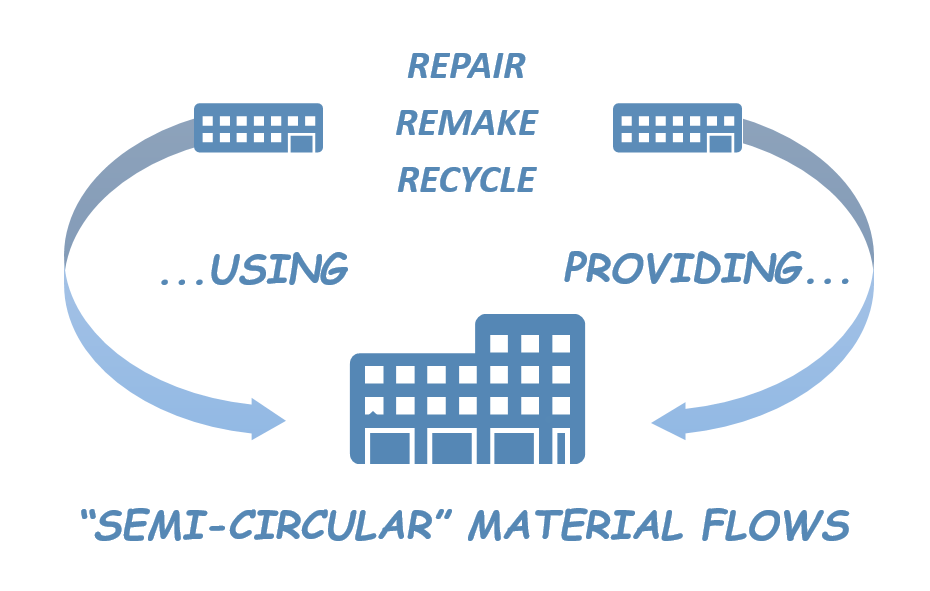

In my conversation with Steve Haskew of Circular Computing (Circular Economy Podcast episode 24), Steve talked about companies that are ‘semi-circular’. What did he mean by that? Steve’s definition was that they either:

- Use circular inputs in their business. This could include recycled materials; waste from another industrial process (industrial symbiosis); reusing existing products or components.

- Alternatively, they circulate their end-of-use resources, by ensuring they flow into an organised recovery and recirculation system. This could include resale, repairs, remanufacture or – as a last resort – recycling. In a circular economy, we aim to recirculate all types of resources: materials, products, equipment, packaging, excess materials, rejects, damages and failures, water, chemicals etc.

Doing more good vs a ‘bit less bad’

What do you think? Is this a sound approach, or is it undermining the ethos of the circular economy?

I feel that it is a good step forward, doing more good (rather than a ‘bit less bad’). Why do I say this? It helps circulate resources and keep them in the system, even though these companies aren’t completely ‘closing the loop’ themselves.

If we think about using circular inputs, this can create demand for newly developing circular services. It can help companies setting up businesses to resell, repair, remake and recycle. Similarly, the end-of-use resource flows (ie circular outputs) help create the markets needed to enable businesses to invest in new services and technologies.

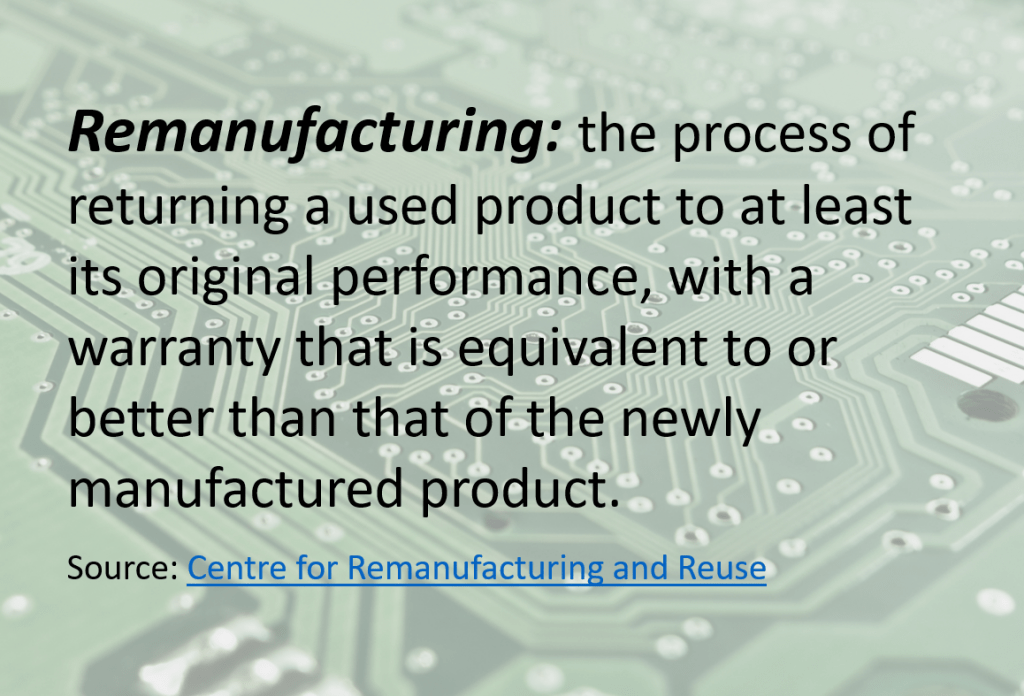

Semi-circular strategies and remanufacturing

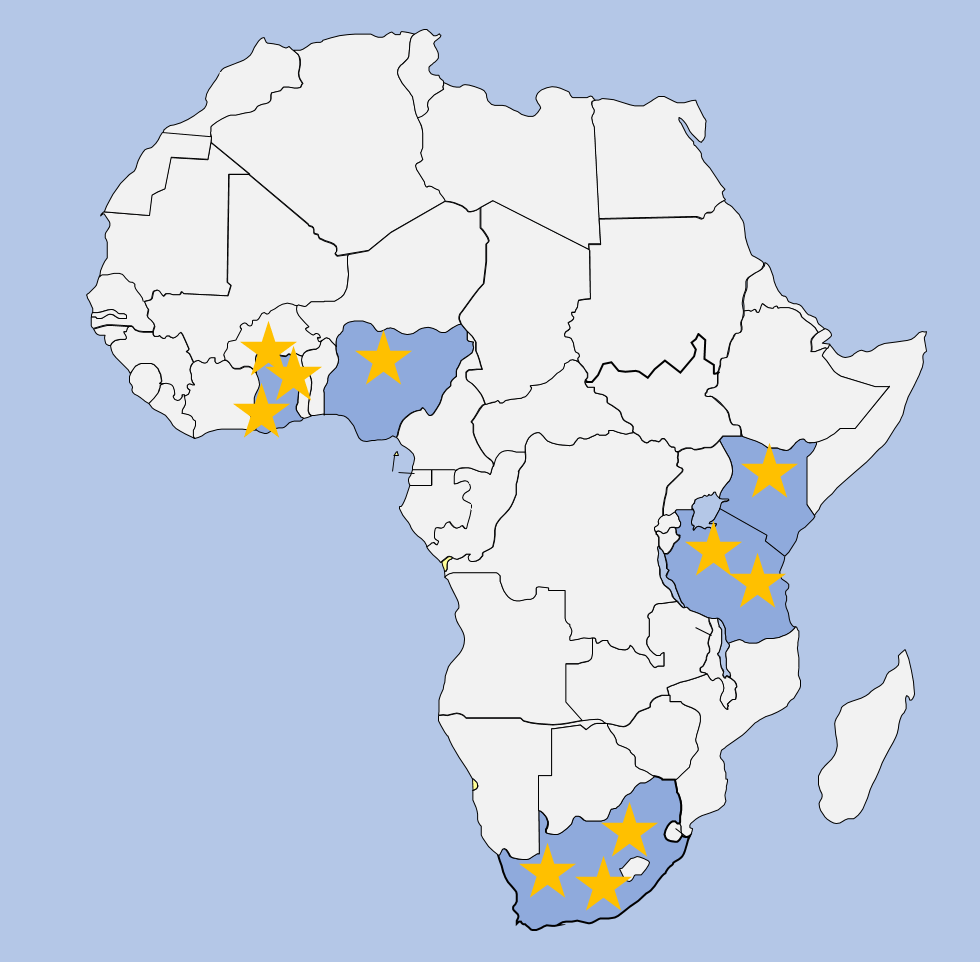

Circular Computing remanufactures high-quality top-end laptops. However, to match demand and supply, remanufacturers like Circular Computing need to work with both kinds of semi-circular organisations.

Some will provide Circular Computing with end-of-use IT equipment, in good-enough condition for remanufacturing. They have sufficient (and regular) volumes of each brand and product specification (processor, screen size, storage media), enabling Circular Computing to sustain economic remanufacturing batch sizes.

On the other hand, some organisations will be customers, buying reliable and robust IT equipment, refurbished, upgraded and tested to meet their users’ needs for the next 3-year use-cycle.

Even better, some organisations will close the loop completely. They may start by buying remanufactured equipment, use it for three years and then feed it back into the remanufacturing process.

However, some laptops will be heavily used (or abused!), preventing their successful refurbishment. It may be possible to ‘harvest’ parts from these machines to reuse in other laptops, or to at least recycle valuable raw materials.

Jargon buster: in remanufacturing terminology, products and components are known as ‘core’.

10 ways semi-circular strategies deliver sustainability benefits

Let’s examine the benefits for those organisations involved in the remanufacturing supply-chain, either buying or providing products.

- Firstly, it reduces reliance on virgin resources, improving resource security in the long term by keeping the components & materials in the system for longer

- This reduces the extraction of virgin metals, minerals and petrochemicals, thus reducing mining waste and associated environmental destruction, pollution of local watercourses and so on. Circular Computing calculates* that each remanufactured laptop saves 1200 kg of virgin resources

- Also, we reduce consumption of energy, water and chemicals. Remanufacturing requires far less of each of these, compared to manufacturing new items. Circular Computing calculates* that each remanufactured laptop saves 190,000 litres of water

- This means we reduce the Greenhouse Gas emissions from the production and supply chain. Circular Computing calculates* that each remanufactured laptop saves 380 kg of CO2

- By recycling end-of-life components (eg damaged, outdated specifications etc), we can regenerate resources

- We reduce risk by using tried and tested equipment instead of the latest ‘new to market’ models

- This means we avoid waste disposal costs by feeding end-of-use products into a remanufacturing process

- On top of this, we reduce e-waste and its associated environmental and societal problems (pollution, toxic materials affecting recycling workers and so on).

- We reduce the cost of providing IT equipment, with significant savings compared to buying new laptops.

- And finally, this enhances your reputation. All these societal and environmental benefits can be included in company sustainability and Corporate Social Responsibility reports, helping to engage customers, employees and other stakeholders.

Semi-circular strategies make sense

That’s a pretty impressive list, highlighting the benefits of supporting remanufacturing and circular economy strategies.

How could you work some semi-circular strategies into your supply chain? Get in touch if you’d like us to help you use circular approaches to strengthen your business.

* Source for Circular Computing resource use figures: https://circularcomputing.com/resources/sustainable-it-calculator/

Catherine Weetman advises businesses, gives workshops & talks, and writes about the circular economy. Her award-winning Circular Economy Handbook explains the concept and practicalities, in plain English. It includes lots of real examples and tips on getting started.

To find out more about the circular economy, why not listen to Episode 1 of the Circular Economy Podcast, read our guide: What is the Circular Economy, or stay in touch to get the latest episode and insights, straight to your inbox…