6 minute read

Who is exploiting the circularity gap in your business?

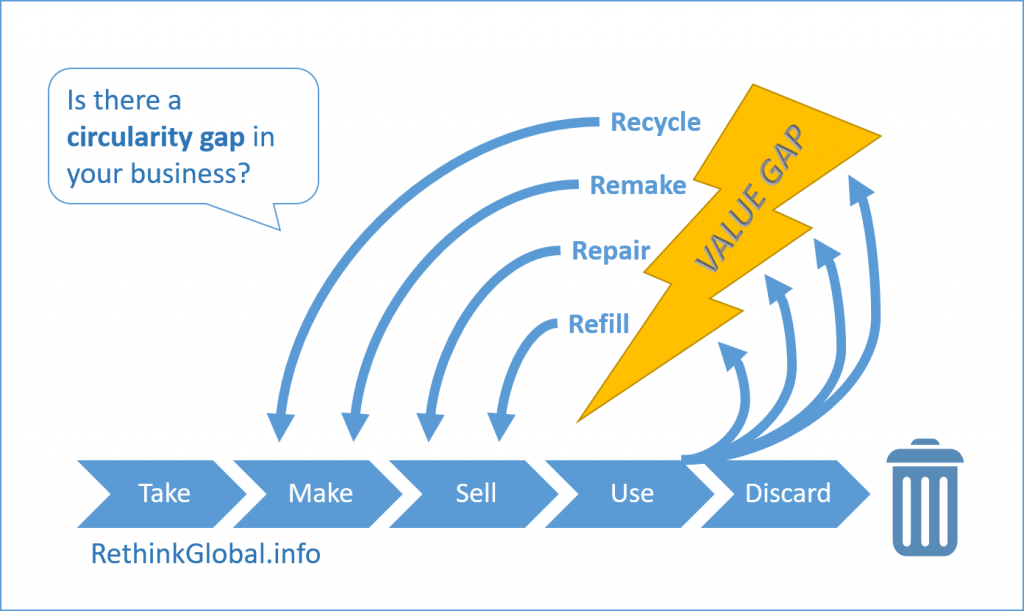

Have you left a circularity gap open in your value chain?

Are you allowing a competitor to extract value from your end-of-use products or materials?

Our ‘linear’ mindsets, focused on growing our business by selling more stuff, can leave us open to a wide range of risks. In the last blog, we looked at some of the risks embedded in international supply chains – currently in the spotlight due to coronavirus impacting production, logistics and global demand.

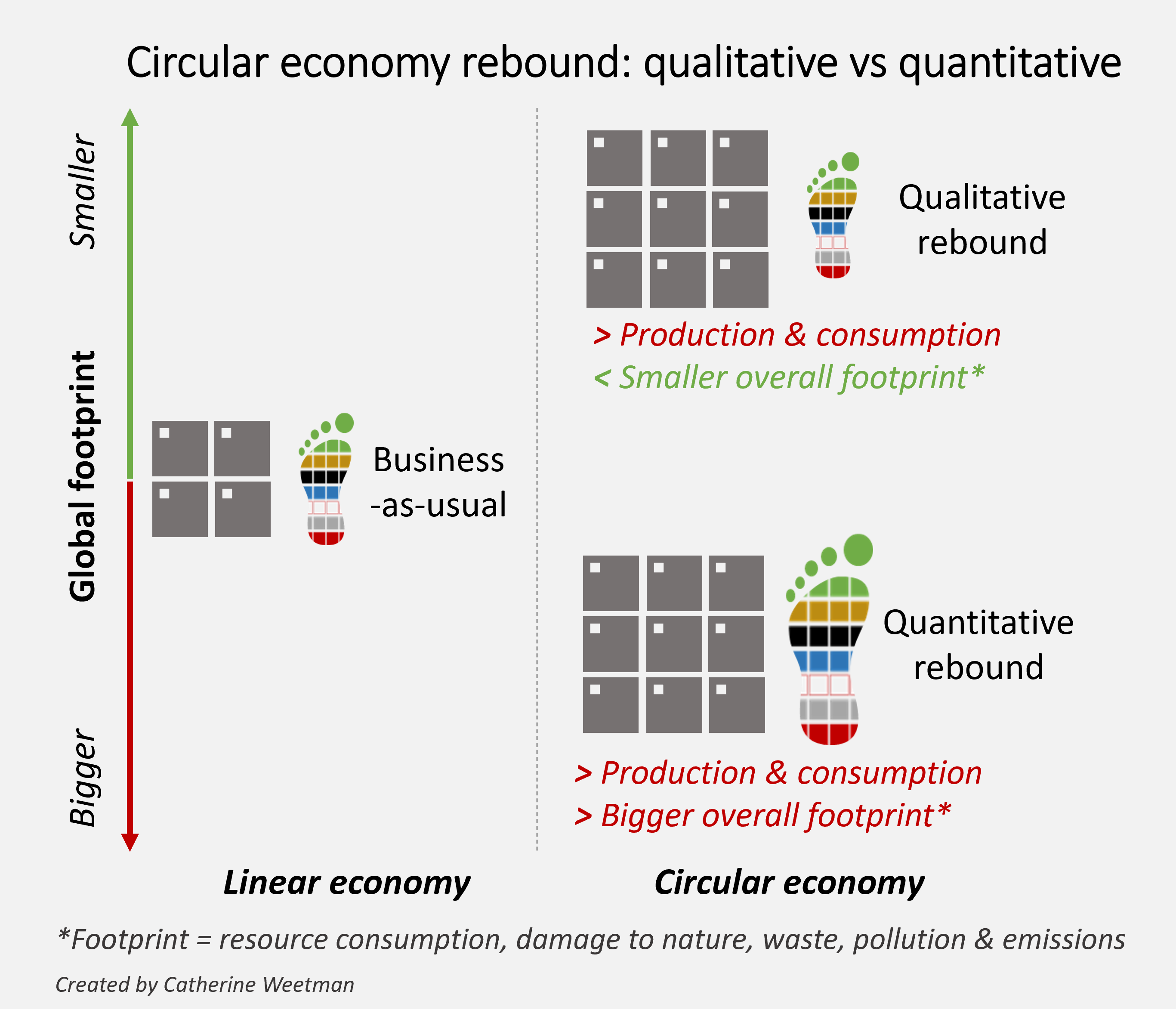

My recent podcast interview with Tom Ogonek, Co-CEO of Close the Loop Inc, highlighted another common risk. By sticking with the linear economy model and allowing your product to be discarded at the end-of-use, you’re allowing value to leak out of your business. If you fail to ‘close the loop’ in your extended supply chain, you leave space for a competitor to step into the gap, to create value from your end of use products.

We’ll explore the circular solutions you can use to combat this, and look at the wider benefits these bring to your business.

Close the Loop

Let’s start with Close the Loop. They make it easy to take back, recover, and reuse your high-value products – so they don’t end up in rivers, landfills – or on someone else’s assembly line. Close the Loop works with major manufacturers of products including print toner cartridges and cosmetics.

One of its early services began when printer brands realised they were missing out on substantial revenue from sales of replacement toner and ink cartridges. These OEM (Original Equipment Manufacturer) replacement cartridges were made in the same way as new ones, and customers felt they were expensive. Meanwhile, ‘grey market’ remanufacturers offered lower-cost substitutes, often by collecting and refilling the OEM cartridge. The grey market refill might be lower quality and not capable of printing as many pages – but few customers would calculate the actual cost per printed page, so probably didn’t notice the value-for-money or quality difference. Even worse, they might blame the poor performance on the printer itself!

The grey market operators even managed to obtain the OEM cartridges to fill. Often, they linked up with charities, offering free postage for the user and a donation to the charity for every used cartridge returned.

Exploiting the circularity gap

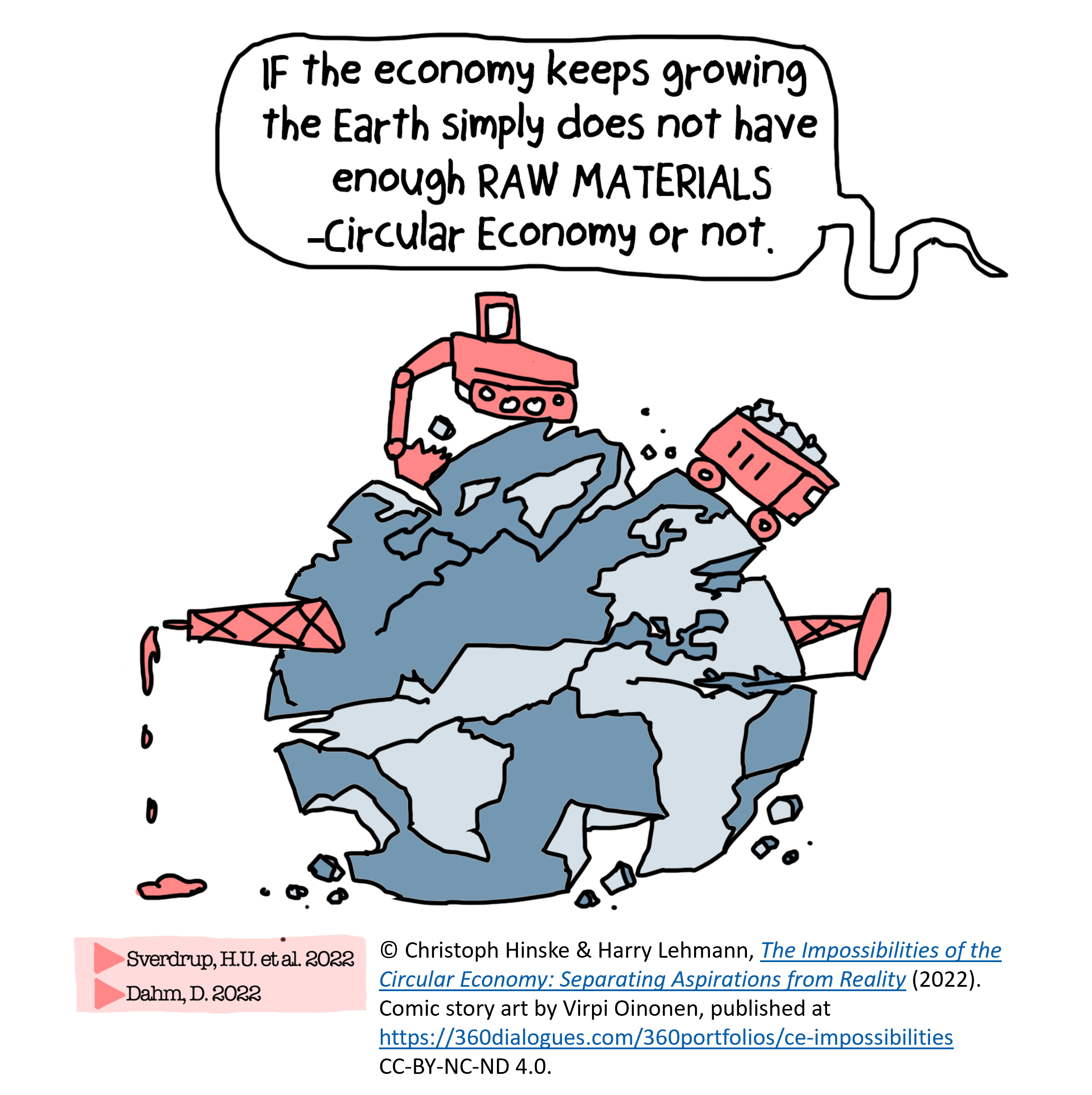

The upshot was that the OEMs were creating robust, durable (and refillable) cartridges, but failing to ‘close the loop’ on their value chains. Making new cartridges instead of refilling used ones meant precious resources were sent to landfill or incineration, wasting value opportunities.

This left a ‘circularity gap’ for those on-the-ball independent remanufacturers to move in, and exploit that opportunity for their own businesses. [Researcher Katherine Whalen and her team, at IIIEE, Lund University, talk about ‘gap exploiters’. These are ‘third-party firms that create value through the re-utilization of existing products’ by slowing down the throughput of products in the system.[i]]

“Breaking an old business model is always going to require leaders to follow their instinct.

There will always be persuasive reasons not to take a risk. But if you only do what worked in the past, you will wake up one day and find that you’ve been passed by.”

Clayton M. Christensen

Circular solutions are better for everyone

What is the circular solution? By working with Close the Loop and providing easy-to-use, cost-effective take-back services, the OEM brands are able to regain control of the cartridges. Now they can refill them to sell to users, capturing the value for themselves.

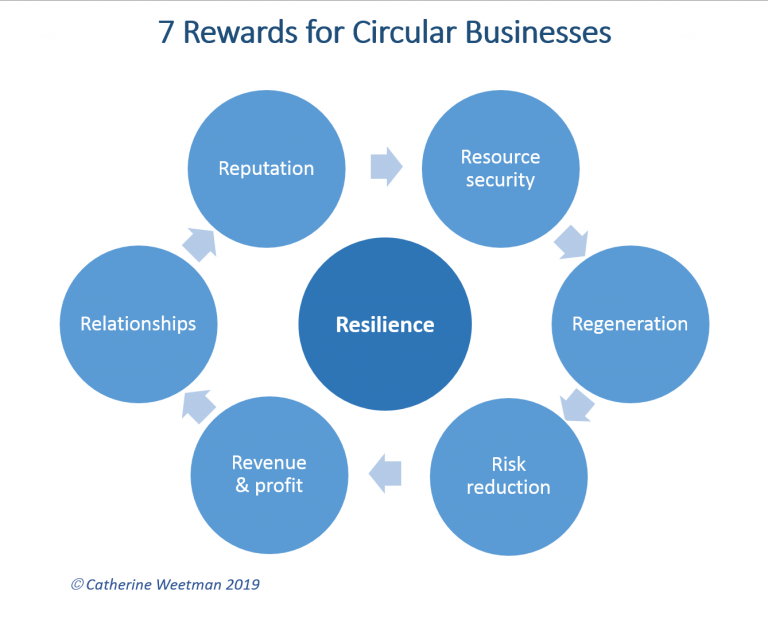

There are other benefits, as we saw in my blog: 7 reasons why the circular economy is better for your business. Providing an easy-to-use take-back service, such as special bins in retailers, or Freepost envelopes, helps customers and employees feel they are working towards zero waste targets. Also, seeing actions to create a circular economy helps build brand trust and reputation.

Some manufacturers are using sensors to monitor ink levels, providing reminders and convenient re-order processes, helping build stronger relationships with the customer. The refill and remanufacturing program reduces the need for virgin materials. This, in turn, reduces risks from volatile costs, future resource scarcity or supply chain shocks (eg the Coronavirus). All of that increases resilience.

Is the problem limited to print cartridges? No. Close the Loop is working with cosmetic brands too, helping them recover end-of-use packaging to prevent it being illegally refilled by unscrupulous imitators.

Circularity gaps are everywhere

These circularity gaps are created by failing to provide an effective take-back and reuse loop for reusable products or packaging. Other gaps include potential for repair and remanufacture, allowing ‘gap exploiters’ to create independent services to refurbish, repair or remake products, often with a ‘like new’ warranty to match. We’re seeing users get more involved in repair with support from iFixit and the Repair Café movement. What’s more, companies are realising that a whole range of products, including high-end watches, handbags and furniture, have potential to be cleaned, refurbished and resold. What’s more, high-quality pre-loved items can command a higher price than the original version when new.

Another gap opportunity is the value of materials in the end-of-life product. Technology products such as computers and smartphones are full of valuable (and sometimes scarce) minerals and metals.

The United Nations Resource Panel tells us that ‘less than one-third of some 60 metals studied have an end-of-life recycling rate above 50 per cent and 34 elements are below 1 per cent recycling, yet many of them are crucial to clean technologies such as batteries for hybrid cars to the magnets in wind turbines.’ There are big benefits: the energy savings from avoiding the use of virgin metals range from 60 to 75 per cent for steel and over 90 per cent for aluminium, according to this UN infographic. Mining and processing metals and non-metallic minerals creates 20 per cent of global greenhouse gas emissions.

Technology brands closing the circularity gap

Technology brands are now developing take-back and reuse offers for smartphones, to compete with ‘buy-back’ specialists like Gazelle and many others . Reverse Vending Machines and ‘machine learning’ can be used to streamline the collection and buy-back process.

Greenbiz tells us that Best Buy‘s electronics takeback program began with in-store parking lot events in 2009 and into a complex logistics operation spanning all of its retail sites. Its 20,000 Geek Squad tech-support representatives, who repair 5 million items a year, also collect electronics from clients’ homes.

T-Mobile offers a phone trade-in service. In the UK, Telefonica launched O2 Recycle in 2009, and by 2019 had prevented more than three million handsets from reaching landfill, saving 450 tonnes of waste from landfill and paying over £225 million back to customers. All devices are data-wiped and either reused or recycled. As many as 95 per cent are in suitable condition to be resold.

Apple offers a Trade In program, with credit towards a future purchase for eligible products. Non-eligible devices are recycled for free. In 2019, an iPhone XS could earn up to US $500 credit. Customers answer a few questions about the device condition, and are given a trade-in estimate. Users are shown how to safely back up and wipe their data, and can opt for a prepaid shipping label, or take it to an Apple Store.

Green Alliance tells us that a reused iPhone retains almost half its original value, whereas recycling recovers less than a quarter of one per cent of the value of a new phone. In other words, reusing the iPhone recovers 200 times more value, as well as increasing Apple’s customer base. Even better, those new customers are likely to buy music and other subscription services from Apple.

Apple – committing to the circular economy

In 2019, Apple committed to a circular economy model (thought without target dates), declaring ‘we want to one day manufacture products without mining any new materials from the earth.’ Apple acknowledges ‘it’s a big challenge. But we know we can make the best products in the world while leaving the planet better than we found it.’

Apple recognises the value of recovering its own resources. Apple’s material recovery robots (known as Daisy) have evolved to disassemble 15 different iPhone models at the rate of 200 per hour. This means each robot could disassemble more than a million devices per year. Apple refurbished more than 7.8 million devices in 2018, diverting more than 48,000 metric tons of e-waste from landfills.

Although the recovered materials represent a tiny proportion of the 60 or so elements found in an iPhone, Apple prioritized the highest-value raw materials based on their environmental, social and supply impacts. In 2019, it opened a Material Recovery Lab and will partner with academic institutions to drive innovation in recycling and device disassembly.

Seven benefits of closing the circularity gap

Closing the circularity gap in your value chain can create new revenue streams, improve resource security, reducing risk (and costs). Providing circular services to your customers can build relationships and strengthen your reputation. Recycling can help regenerate resources, helping create a better world – and a more resilient business.

We can help you examine your linear risks and spot circular opportunities – drop us a line to find out more.

Further resources

For more on value-mapping, have a look at this tool from Cambridge University.

To find out more on the system-level implications of the linear economy, read the latest Circularity Gap Report from Circle Economy and others. The first report, in 2018, analysed global resource stocks and flows, to conclude that ‘Our world economy is only 9.1 per cent circular, leaving a massive ‘Circularity Gap’. Now, we are wasting more and recycling less, meaning our world economy is just 8.6 per cent circular.

[i] Whalen KA, Milios L, Nussholz J (2018) Bridging the gap: barriers and potential for scaling reuse practices in the Swedish ICT Sector. Resources, Conservation and Recycling; 135, pp 123-131. Available online: lup.lub.lu.se/record/2783e403-5f84-4568-9dc1-02a56f5ff [accessed 21 November 2019]

Catherine Weetman advises businesses, gives workshops & talks, and writes about the circular economy. Her award-winning Circular Economy Handbook explains the concept and practicalities, in plain English. It includes lots of real examples and tips on getting started.

To find out more about the circular economy, why not listen to Episode 1 of the Circular Economy Podcast, read our guide: What is the Circular Economy, or stay in touch to get the latest episode and insights, straight to your inbox…