Is circular sustainable packaging high on your priority list? Or are you risking reputation damage through single-use, non-recyclable and badly designed packaging – which is also costing your more money?

Growing public concern about plastic waste is persuading many companies to re-examine their packaging strategies. Innovative businesses are starting to use circular economy approaches to develop better solutions and reduce costs.

Many of us are noticing the amount of plastic we discard each week – much of it not recyclable. The local authority may collect semi-rigid containers, bottles and pots, but not single-use plastic bags, films, wrappers, cartons and trays. Too many products don’t have information on the pack, to help people understand what the material is, or how to recycle it.

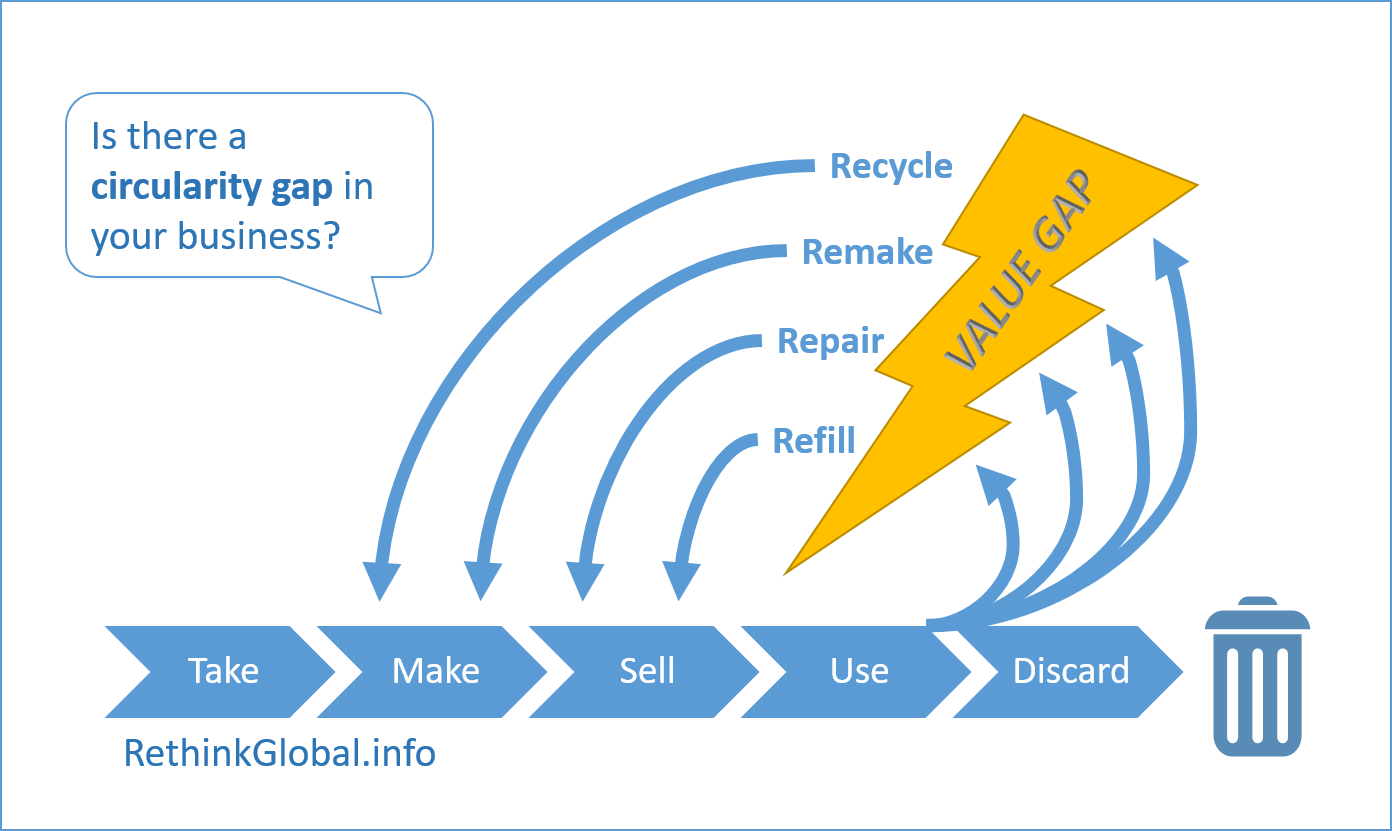

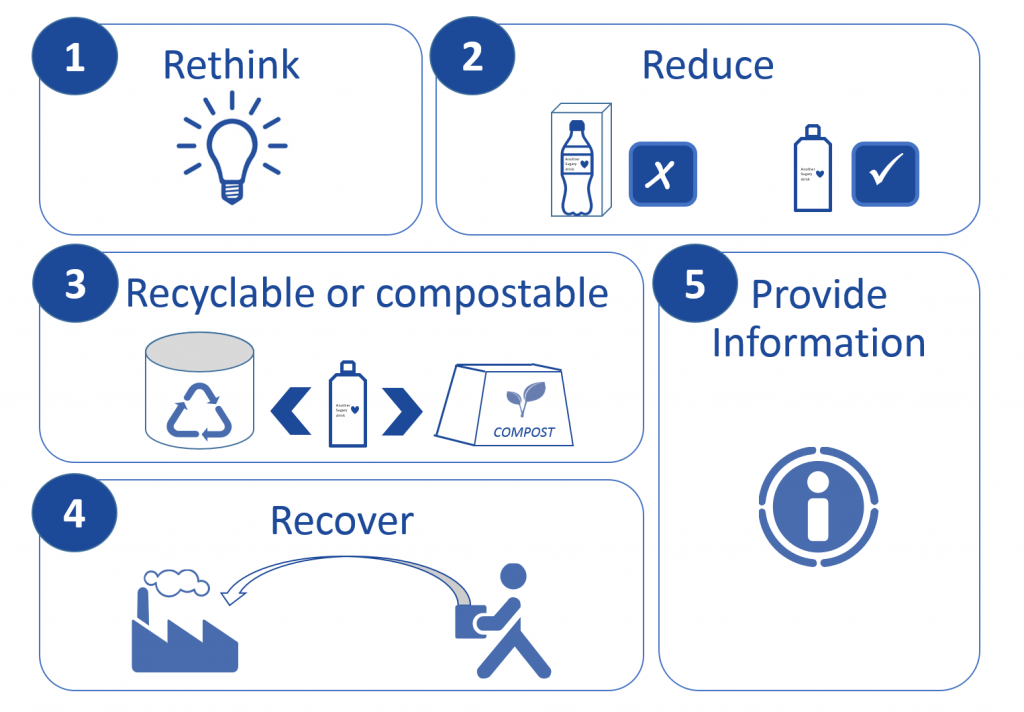

Circular principles can provide us with a design ‘checklist’[i]to use, so we can make it more sustainable, improve the user experience, and save money.

1. Rethink and redesign

Is all the packaging necessary? Cosmetic brand Lush sells soaps in ‘naked’ packaging, and plastic-free supermarket aisles (and even whole supermarkets) are popping up.

How could you redesign the packaging and improve the volume density, minimising both materials and environmental footprints? Consider transit packaging too – could you get a better ‘fill’ on the pallet base and available height: improving utilisation of warehouse space, delivery vehicle and so on. Designing for supply-chain efficiency helps reduce costs for the company and its retail customers, but few companies tap into the knowledge of their logistics teams. According to a report by McKinsey, for two products of identical volume, more rectangular packaging can increase packing density by up to 40%. Move the product, not fresh air!

The flat bottle from Garçon Wines is a brilliant example of innovative redesign. Garçon Wines’ eco, flat wine bottles are made entirely from pre-existing material; 100% post-consumer recycled PET. The bottles were designed to be easily, fully and widely recyclable after use in most markets. Garçon Wines says that a “product is much easier and more likely to be recycled if all components can pass through the same recycling stream which is why we use PP/PE caps and labels.” This helps prevent plastic from ending up as waste in landfill, or litter in the environment.

Compared to a round, glass wine bottle of the same volume, Garçon Wines say their bottles are 87% lighter and 40% spatially smaller. This improves logistics (for example, one bottle will fit through a typical home letterbox), reduces costs of storage and transport, and at the same time, reduces the wine industry’s supply chain carbon footprint.

Here’s another aspect to think about – will the user find it easy to get it into a recycling stream? This may depend on how and where the product is used, and therefore where people will remove the packaging. You might consume a soft drink at work, at an event, in the street, or at home.

Try to design for the majority of scenarios, not the example that’s the easiest option for the manufacturer! Be careful to avoid it becoming petrochemical-based plastic waste. If it ends up as litter it can pollute watercourses. Eventually, it may break down into microplastics, meaning there’s a risk that it poisons or harms living creatures (including humans).

2. Reduce the materials

Aim for fewer and simpler materials, to improve resource efficiency and aid recycling. Could you lightweight the design, using thinner-walled bottles or cans to reduce materials, costs, energy and GHG emissions?

Could you print onto the pack instead of applying a label, thus reducing printing costs as well as improving recyclability?

If it’s likely to go into ‘mainstream’ recycling services, then you should make sure the design simplifies recycling. Use materials that are recyclable and recycled, and try to avoid multiple materials, laminates and dark colours which are difficult to sort, separate and recycle.

3. Recyclability

Can you make it easier to recycle, perhaps by using alternatives to plastics, including glass, metals, cardboard and paper? Otherwise, aim to use renewable, bio-based materials, so at the end of life, waste becomes food for nature: in other words, compost.

Bio-based materials include paper/card, cellulose, or PLA (polylactic acid) from cornstarch or sugar beet. Ecovative uses mycelium to convert agricultural waste into a strong, lightweight protective pack.

Be careful though: certifications for ‘compostable’ and ‘biodegradable’ indicate that the materials will break down and won’t prevent decomposition of surrounding organic waste. Those certifications don’t guarantee the use of bio-based materials.

4. Recover for reuse

Could you set up systems to recover primary, secondary and transit packaging for your own reuse, or as part of a sector collaboration? There are systems for beer kegs and returnable bottles, and now there is a solution for e-commerce delivery packaging, with RePack.

5. Provide information!

Encourage recycling and recovery, by providing clear information about the packaging materials, and the options for end-of-use recovery or recycling.

Summary

Is your packaging future-fit, and is it making a positive contribution to society and nature? Is it meeting your customer’s needs: in delivery, in use and at end-of-use?

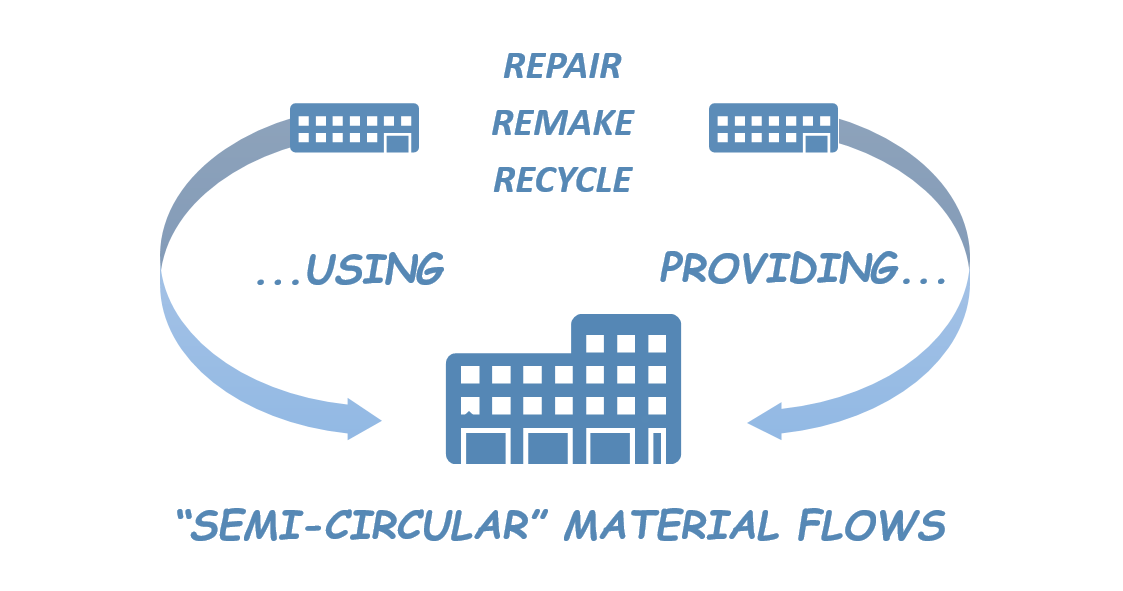

If not, can you rethink, reduce or recover it for reuse? How best can you design it so that it’s not discarded, and that waste becomes ‘food’ with a value? If you can turn it into a feedstock (or input) for new packaging, you might create a revenue stream instead of paying to dispose of it.

Circular economy and ‘zero waste’ approaches are more sustainable, improve the user experience, and save money.

This blog was first published on the Kogan Page website in 2018

[i] An excellent online course on Sustainable

packaging design for a circular economy from TU Delft

To find out more about the circular economy, why not listen to Episode 1 of the Circular Economy Podcast, read our guide: What is the Circular Economy, or find out more about Catherine’s award-winning book: A Circular Economy Handbook for Business and Supply Chains.

Why not stay in touch and get the latest episode and insights, straight to your inbox…