The Textile Review, founded by Katie Briggs, is making fabric use more circular and sustainable, with services to repurpose and reuse textiles.

It connects businesses, designers and students, matching ‘I have’ with ‘I need’ and creating value for both providers and users.

The Textile Review aims to ‘help end the issue of single-use textiles across event and design industries’.

5 minute read

In setting up the Textile Review, Katie Briggs used her experience of the live events sector to pinpoint a problem and to spot the opportunity to create a circular solution. Conferences, exhibitions and other live events use significant quantities of fabrics, often just for 2-3 days and with little wear and tear. Typically, these fabrics are then disposed of. However, over the past few years, increasing quantities of clothes and other textiles for recycling, combined with a trend towards lower-quality of both fabrics and clothing has reduced the value of end-of-use textiles.

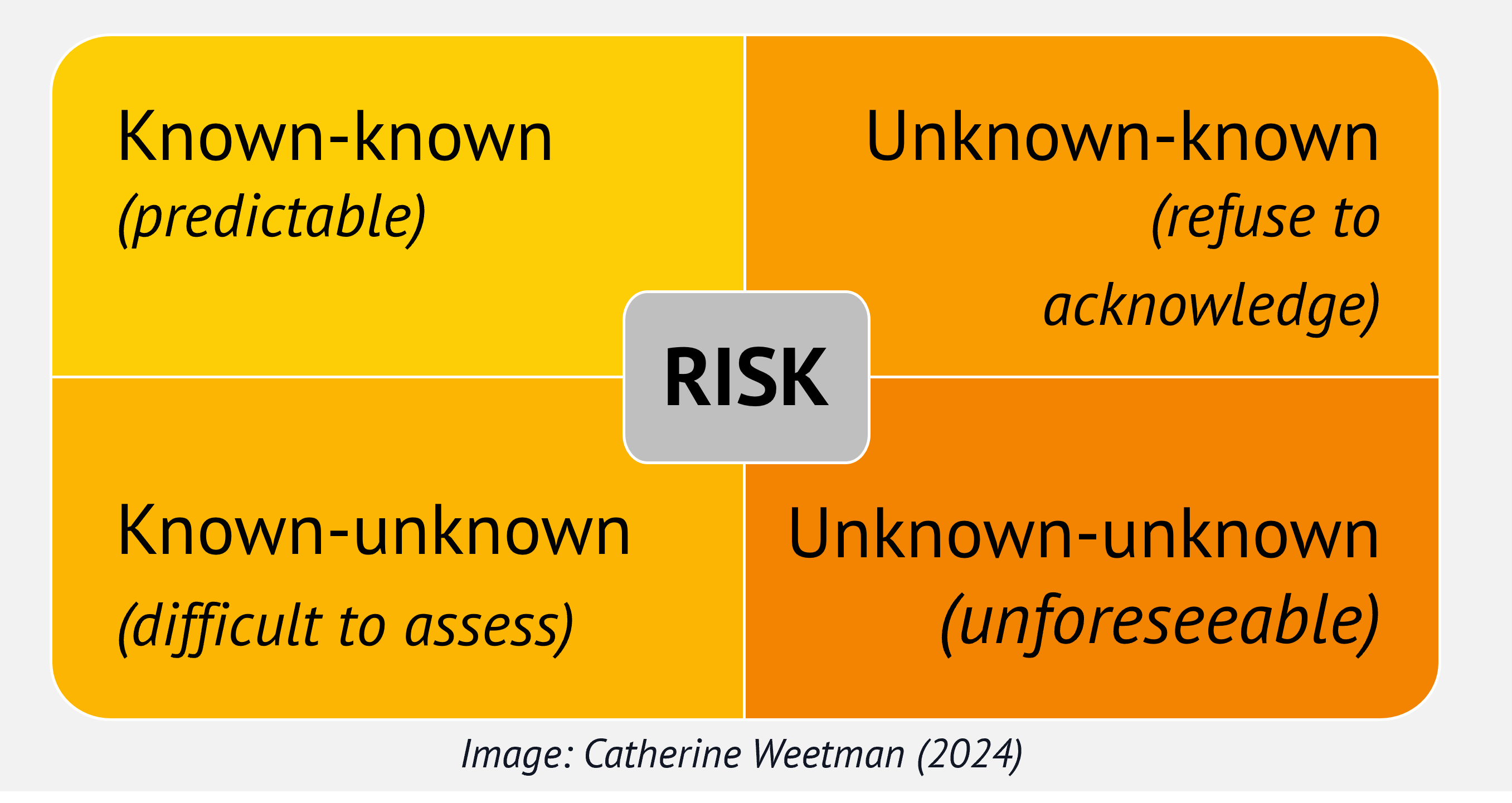

These days, in regions like Europe, it is common to have to pay for the collection, sorting and recycling of end-of-use textiles. This is a form of ‘negative value’. What do we mean by that? Even though the material appears to be useful, the costs of logistics, transport, sortation and resale outweigh the potential revenue from resale markets.

The problem with fabric...

You’re probably aware of the broader sustainability issues for textiles. As Katie says, “the textiles industry is one of the biggest contributors to pollution on the planet. It’s up there with the likes of oil. Most manmade fabrics, such as polyester and nylon, account for well over half of textiles produced worldwide – using synthetic chemicals, mostly based on petroleum.”

We might assume that natural fabrics are better – but not necessarily. Cotton is a thirsty crop, using thousands of litres of water to grow each kilogramme of cotton. It is also the most pesticide-intensive crop on the planet.

The events sector, together with its corporate customers, recognises the sustainability issues associated with staging events and conferences, with resources, building space and equipment dedicated to the event for just a few days. Some resources, such as furniture and audio-visual equipment, can be used many times. But others, including textiles, bags, banners and promotional items are effectively ‘single-use’ items.

The reuse puzzle

Once she had identified a specific problem – of barely-used fabric going to waste – Katie needed to solve the other half of this ‘reuse’ puzzle. What kinds of customers would value these materials? She wanted to identify groups who would use these types of textile. Groups prioritising sustainability improvements would value the ability to source good quality, yet pre-used fabric. By connecting with these groups, The Textile Review provided benefits, including saving money (a high priority for the students!) and being able to demonstrate they were doing more good for our planet and society. Reusing textiles avoids the energy, water and chemicals involved in creating the fibres (farming or petrochemical production) and turning them into finished textiles. Similarly, reuse avoids the energy involved in logistics and transport, often through international supply chains.

Katie found that both fashion designers and fashion design students use calico and muslin regularly. In addition to being inexpensive, they ‘drape’ well and are easy to work with. This makes them ideal for testing the fit of a garment and to make new patterns for each different size of garment.

Muslin is the ‘go-to’ fabric for dressmakers and garment designers. For this reason, a “muslin” is now the generic term for a test or fitting garment, regardless of the fabric used to make the prototype.

Muslin (mŭz′lĭn) is a cotton fabric of plain weave. It is made in a wide range of weights from delicate sheers to coarse sheeting. It gets its name from the city of Mosul, Iraq, where it was first manufactured. Early muslin was handwoven of uncommonly delicate handspun yarn, especially in the region of what today is Bangladesh. It was imported into Europe for much of the 17th and early 18th centuries. Source: Wikipedia

Calico (/ˈ k æ l ɪ k oʊ /; in British usage since 1505) is a plain-woven textile made from unbleached and often not fully processed cotton. It may contain unseparated husk parts, for example. The fabric is far less fine than muslin, but less coarse and thick than canvas or denim. However, it is still very cheap owing to its unfinished and undyed appearance. Source: Wikipedia

I have / you need

By finding customers who need these types of fabric and want to reduce their environmental footprint, Katie can create value from the end-of-use textiles. As an example from a different sector, a UK food manufacturer decided to look for ways to recover value from everything in the deliveries from its farm suppliers. Its processes included washing the vegetables supplied by the farms. First, it separated the residue into soil and stones. It then sells the soil back to the farms, and ‘grades’ the stones (sorting by size). The extra process separates the stones into grades of gravel, packing them into small bags so they to be sold to garden centres. Why is this better? Because, compared to selling the stones for road construction, it achieves a significantly higher price per tonne.

Textile Symbiosis

The Textile Review highlights the benefit of reuse, which uses less energy, transport and processing (and associated costs) compared to recycling. Reuse flows like this are similar to Industrial Symbiosis, and help to ‘slow the flow’ of materials. Indeed, If the fabric is recycled after its final use, then we have closed the loop to create a circular economy.

Industrial symbiosis involves separate companies collaborating to improve competitive advantage, through the physical exchange of materials, energy, water, etc.

Customers can buy in small quantities of a metre upwards, avoiding waste from having to buy minimum volumes of fabric. The Textile Review offers both buying and hiring services, giving more flexibility to fabric users and reducing their capital expenditure costs. Hiring also encourages additional use-cycles for the fabric, so its customers reduce their environmental footprint further.

Knowing about the reuse options might influence the event companies’ choice of fabrics too, encouraging them to specify those fabrics which are more attractive to secondary users.

The Textile Review provides other benefits to its buyers and sellers:

- Transparency: including details of where the fabrics go, and where they’ve come from.

- Impact metrics: with each type of textile weighed, and relevant sustainability metrics provided. Customers can then track the positive impact of fabric reuse.

Customers can use this information in their marketing and sustainability communications, helping improve their Corporate Social Responsibility credentials.

Additionally, the Textile Review operates as a social enterprise. This means at least 50 per cent of all profits are used to make a positive impact. Katie believes this is “the future of business and by working with us you’re encouraging that to come true.”

Circular economy benefits

The Textile Review’s circular strategy is to slow the flow of resources, by keeping textiles in use for longer. It does this by providing a reuse platform to connect ‘I have’ with ‘I need’ and focusing on niche markets that use specific types of fabric.

Ultimately, we can see how The Textile Review creates value in many different forms, for both the providers and users of repurposed fabrics:

- Reducing the costs of fabric disposal or purchase

- Reducing the organisation’s footprint – using less energy, water, materials, labour and emitting less waste and pollution – and being able to ‘tell the story’ with sustainability metrics

- Fair and ethical – transparency of what is used and where it comes from/ goes to

- Inclusivity – supporting a social enterprise which contributes to community projects

This helps improve reputations too, through being able to tell the story of responsible, circular and more sustainable approaches.

As a result, these benefits help those involved feel proud of what they are personally doing too. They can tell their friends and colleagues about how they are helping make a better world. That, in turn, encourages them to keep making a little bit of extra effort to donate or buy pre-used fabric, instead of continuing with ‘take, make, waste’.

Learn more:

- Read about how muslin is used in the events sector, and some of the ways The Textile Review is repurposing muslin in Katie’s blog: Fabric Focus: Muslin

- Blog: Why reuse is #1 tool in the circular economy toolkit

- Blog: The best circular strategy is NOT recycling

Catherine Weetman advises businesses, gives workshops & talks, and writes about the circular economy. Her award-winning Circular Economy Handbook explains the concept and practicalities, in plain English. It includes lots of real examples and tips on getting started.

To find out more about the circular economy, why not listen to Episode 1 of the Circular Economy Podcast, read our guide: What is the Circular Economy, or stay in touch to get the latest episode and insights, straight to your inbox…