Rethinking procurement for a circular economy

The circular economy opens up value opportunities in every sector, worldwide.

Circular approaches reduce risk, whilst increasing agility and flexibility. Business and society become resilient, sustainable and fit for the future.

Procurement teams can lead the way, both internally and through suppliers.

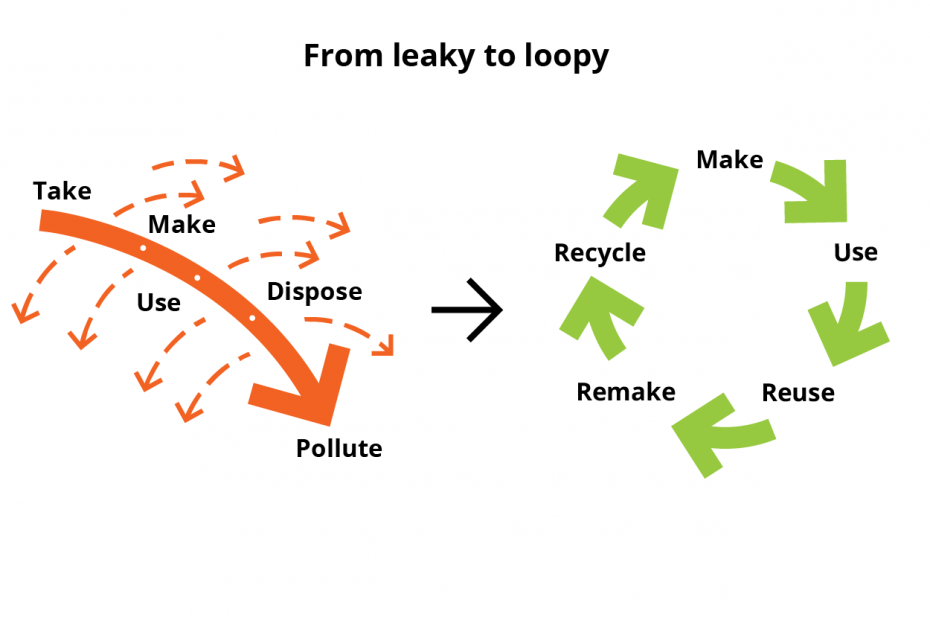

Most industrial processes take some materials, make something, sell it, and at end-of-use, we throw it away – a ‘linear economy’. Resources ‘embedded’ along the process – energy, labour, water and materials – are also wasted.

Our increasing pressure on earth systems is pushing them beyond safe limits.

Increasing pressure on society is creating hardships, unrest and conflict.

Demand is outstripping supply.

How can we redesign the negative feedback loop of destruction and depletion of resources and living systems, so we regenerate what we need to have enough, for all, forever?

Opportunities - and challenges

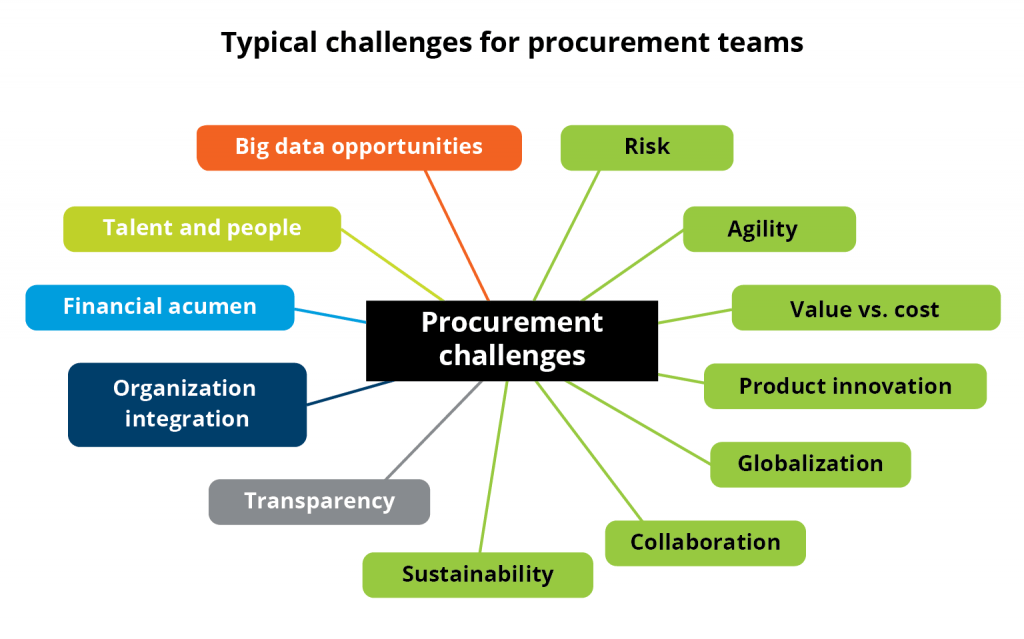

The diagram below shows typical challenges for procurement teams. Globalization has increased choices and reduced costs, but involves extended supply chains ‘tiers’, obscuring the risks and challenges at each stage.

Three billion new consumers are set to join the global market between 2010 and 2030. That presents a fantastic business opportunity, but with complex challenges: how do we meet all our needs in a world of finite resources, land and water?

A useful open-source tool is the Future Fit Business Benchmark, based on the four system conditions of the Natural Step:

- cycle finite materials;

- use safe, renewable or recycled materials;

- regenerate living systems to secure abundant natural resources and ecosystems;

- create meaningful jobs and support local communities.

The circular economy supports these criteria. It is an intelligently designed, ‘whole system’ approach, replacing consumption with use, with business models that recover products and materials. Aiming for 100% yield from each resource, it creates more from less, with ‘waste’ converted to inputs. An example is processing oranges to make juice: biorefining creates valuable by-products; pectin, pulp and zest go into food manufacture; orange essential oils are valuable for pharmaceuticals and cosmetics; and citrus peel creates a silk-like textile.

Inputs are sustainable: renewable or recycled from supply chain waste or end-of-life products. Circular products last longer, are used more intensively and re-used, with efficient disassembly and separation of each material for recovery. The tightest loops create most value: re-use, reselling, and then repair and remanufacture – recycling is the last choice.

The circular economy decouples products and services from resource consumption, going much further than resource efficiency and recycling. It reduces ‘externalities’ including pollution and deforestation, and transfers jobs from extraction and mass-production to service, repair, remaking and resource recovery.

How does the circular economy support the Sustainable Development Goals?

Cycling finite materials and using sustainable renewable materials, including water and renewable energy, helps both people and planet. Local flows and business models designed to encourage durability, repair-ability and reuse all help reduce waste and improve productivity. Resource efficiency, recovery of process inputs and converting ‘waste’ into new inputs and by-products reduces cost, creating new revenue streams and employment. Remanufacturing and repair creates markets for more affordable, high-quality products and equipment.

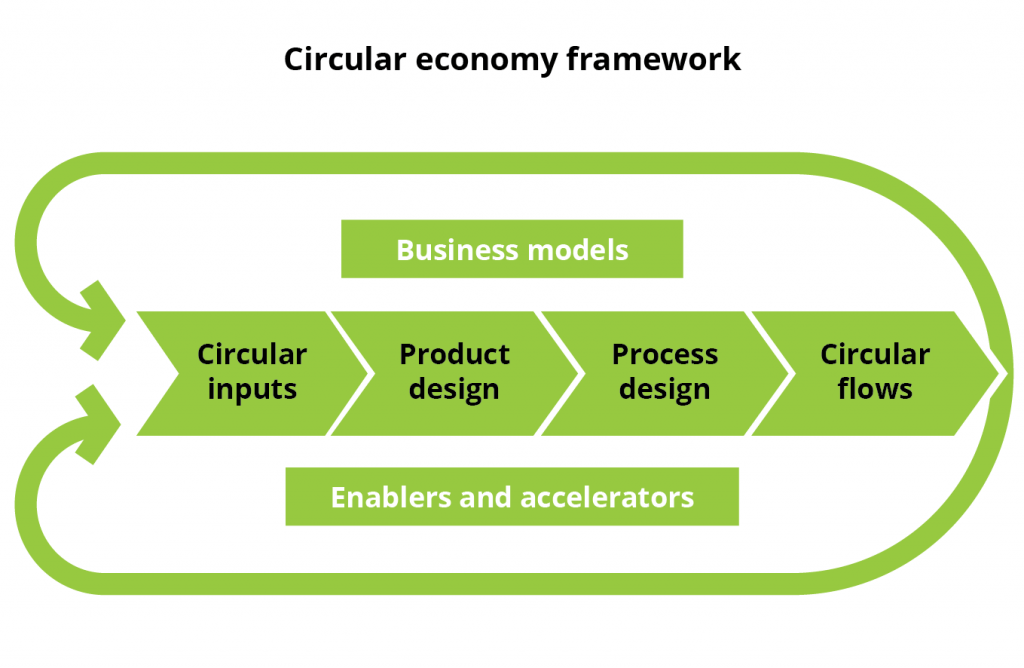

This circular economy framework, from Catherine Weetman’s book A Circular Economy Handbook for Business and Supply Chains, highlights intervention points along the value chain. These are all the points where you can intervene in the business ecosystem to make things more circular

Circular inputs

Materials should be safe and have secure supplies: either recycled or renewable.

Exciting innovations use abundant, natural materials, such as algae for fibres and leather from fish skin.

A company grows mycelium from waste straw to use in packaging, home and construction materials.

Another company collects and sorts textile waste from all over the world, creating high quality yarns for a wide range of apparel, home, and industrial products, that can be recycled again into new yarn, for a ‘closed loop’ solution.

Product designs

Circular designs use less, are durable and can be re-used.

For example: modular houses create jobs where they are needed, and smart ideas enable rapid construction above existing car parks. Manufacturing is more efficient than site construction, with higher production standards and reduced waste.

A start-up business is improving the end-to-end lifespan of mobile phones, including use, reuse and safe recycling. The smartphone has a modular, durable and rugged design – should it need repairing, you order the parts direct and swap out the module with a screwdriver. This company is building a fair-trade supply chain, sourcing materials that support local communities, not armed militias, starting with conflict-free minerals from the DRC.

Process design

In the circular economy, manufacturing processes aim to use less, use renewables and convert waste into resources.

You can now procure solvents as a service: reusing your recovered resources and by-products, or selling them to others.

Biorefining is developing, extracting valuable nutrients and chemicals from waste streams.

Circular flows

At the end of use, we want to recover the product, component and materials for reuse, remanufacture or recycling. When we do this, we are improving the economics and effectiveness of recovery.

Exciting innovations include a new design of textile thread that dissolves when subjected to low-level microwaves, enabling easy separation of textiles, buttons, zips for recycling and reuse.

Other electronics circular projects include post-consumer recycled plastics in Personal Computers, and packaging made from waste wheat straw.

Remanufactured products are high quality, durable, with the same warranty as new versions – but cost less. For major engineering and industrial equipment producers in America and China, it is an extremely profitable part of their business, and now Europe is seeing its potential.

Reuse and sharing platforms are gaining traction: enabling exchange of resources within and between organizations.

Business models

A range of models enables servitization, collaborative consumption, and performance contracts are evolving, with established examples including photocopiers, ‘tyres by the mile’ and aircraft engines: airlines buy ‘power by the hour’ and both parties share objectives for efficient performance and no breakdowns!

Procurement opportunities

How can the circular economy help with those procurement challenges?

- Are your suppliers facing risks, such as water scarcity, soil degradation and climate disruption? Could they swap something toxic, scarce or expensive for recycled or renewable resources? Can you support smaller suppliers with tools and training, help them diversify with new by-products and co-products, and become more resilient? Could precision farming or other regenerative practices help them – and help secure your long-term supplies?

- How can you develop relationships and shared value opportunities with your suppliers? Can you re-specify materials or equipment to improve agility, perhaps by creating the flexibility to use virgin or recycled materials?

- Could you create new value (and build reputation) through more sustainable sources, longer-term win-win supplier partnerships, or by generating revenue from waste?

- How can you work with suppliers – and across your business – to drive product and service innovation, and develop future-fit solutions?

- Circulating products, components and materials supports local flows, reducing reliance on those opaque global sources.

- Could you collaborate with suppliers or exchange by-products with local organizations?

- Circular, sustainable approaches fulfil the Future-Fit system conditions, transforming business, supporting the SDGs and creating enough, for all, forever.

Getting started

Wherever you are on the sustainability journey, there are opportunities for procurement. Could you start with back office categories, facilities management and consumables? Risk assessing key services and materials could produce some quick wins and get buy-in from other stakeholders. Next phases might include packaging; new products or services; then core business items. Could you encourage suppliers to develop circular approaches, creating a ‘win-win’ solution? Are they supplying something problematic, perhaps non-recyclable packaging? Could you negotiate a discount for returning end-of-use items when purchasing replacements?

Future-fit: enough, for all, forever

The circular economy is gaining traction with business leaders, governments and cities: using and sharing instead of consuming resources, with safe, secure and renewable materials.

Find out more about the circular economy here