Researching for my new book, A Circular Economy Handbook for Business and Supply Chains, I found lots of forward-thinking businesses using the circular economy to create new products, open up new markets, and deliver new value for their stakeholders.

Global growth and ‘consumption’ continues, fuelled by a huge upsurge in people with income to spend – ‘consumers’. Families around the world are earning more, and improving their standards of living. This is a fantastic business opportunity – but we live in a world with finite resources: metals, minerals, fossil fuels, and available land, water and clean air. Demand is outstripping supply.

I worry that business leaders are focussing on resource efficiency and ‘doing less bad’ – instead of rethinking their products and services to reduce risks, improve resiliency and ‘do more good’ by regenerating and recovering resources. As an example, early biofuels used specially grown crops – competing for land with food and fibre crops. Newer biofuels use waste from food or fibres – gaining more value from the same crop without needing extra land.

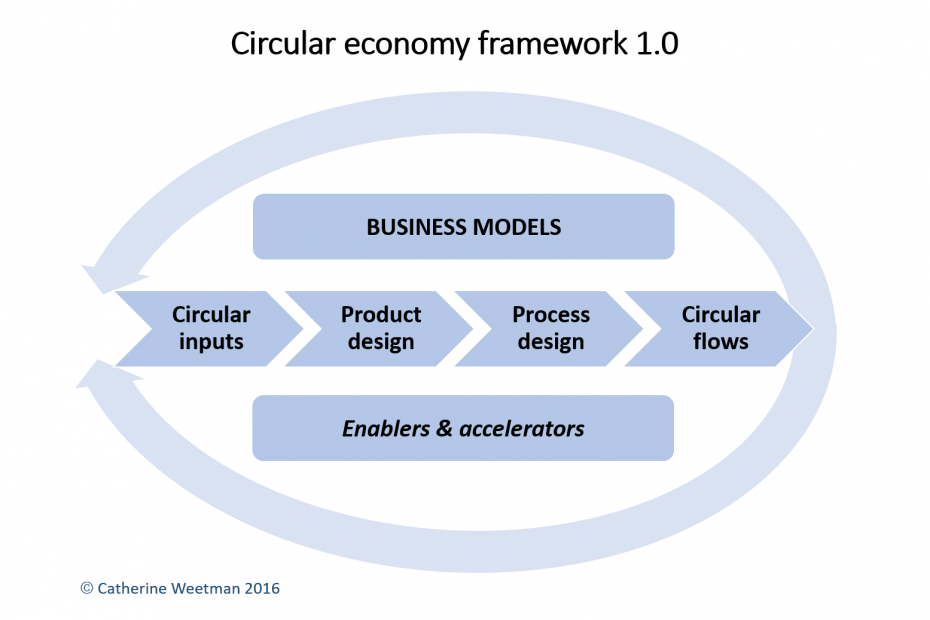

The circular economy unlocks this problem, by ‘decoupling’ resources from consumption. Switched-on businesses are re-thinking product design, material choices, business models and supply chains.

‘… The goods of today become the resources of tomorrow at yesterday’s prices…’ Walter R Stahel

Researching my book I noticed that the list of companies creating circular solutions was growing fast, across both sectors and geographies, and so I started my own case study database. What is really exciting is that most of these examples are small business and start-ups, proving that you can benefit from circular economy approaches without a big R&D budget.

The World Economic Forum (WEF)aims to accelerate the circular economy through Project Mainstream. [Part of the World Economic Forum’s Circular Economy initiative, Project MainStream was run in collaboration with the Ellen MacArthur Foundation and McKinsey & Company as the knowledge partner. It aims to tackle ways of scaling the circular economy through materials management, information technology and business model innovation, among others. The WEF’s Circular Economy community can now be found here.] Global brands including Dell, IKEA, Patagonia, Philips and Renault are embedding circular approaches into their businesses, but my concern is for the vast majority of organizations. Misperceptions that the circular economy either needs complete redesign, or is just another term for ‘resource-efficiency’, almost create excuses for inaction.

A common barrier seems to be ‘we need to focus on cost and resource-efficiency; we haven’t got the luxury of investing in new products or processes’. Hundreds of organizations are creating new value through recovery, reuse, repair, remanufacturing and recycling materials. They are developing by-products, de-risking their business models and getting closer to their customers. It is often easier to do something exciting, disruptive and compelling in industries that have been in steady-state mode for too long.

This spurred me on to pull together a broad range of insights and examples in my book, to spark ideas and highlight the wealth of ‘circular’ opportunities to create new value and access new markets. From Ananas Anam, learning from traditional methods used in the Philippines to make luxurious cloth, Piñatex™, from pineapple leaves, to iFixit, a wiki-based site teaching people how to fix almost anything; the book arms readers with a host of examples, covering a range of industry sectors across the globe. Examining material choice, product and process design, with supporting business models, there is a wealth of information to inspire your journey towards circular, ‘future-proofed’ products and services.

Want to know more? For a quick intro, try this 3 minute video from the Ellen MacArthur Foundation, or learn more about the drivers and opportunities in this 2 minute film from the World Economic Foundation.

This article first appeared on KoganPage.com

Save