On Earth Day: three ways you can use the circular economy to ‘do more good’ for our living planet, and strengthen your business.

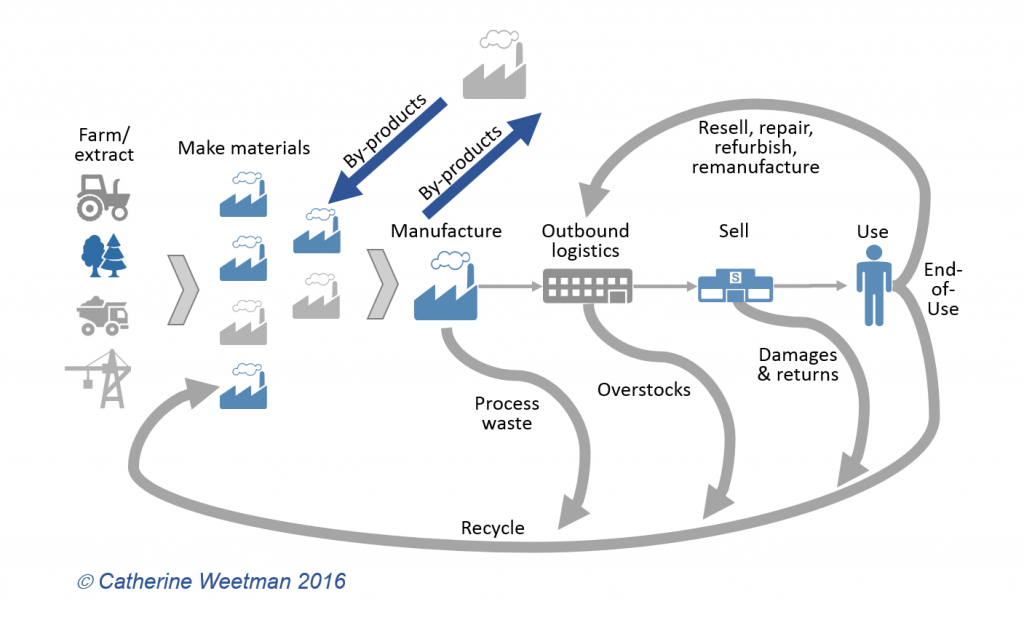

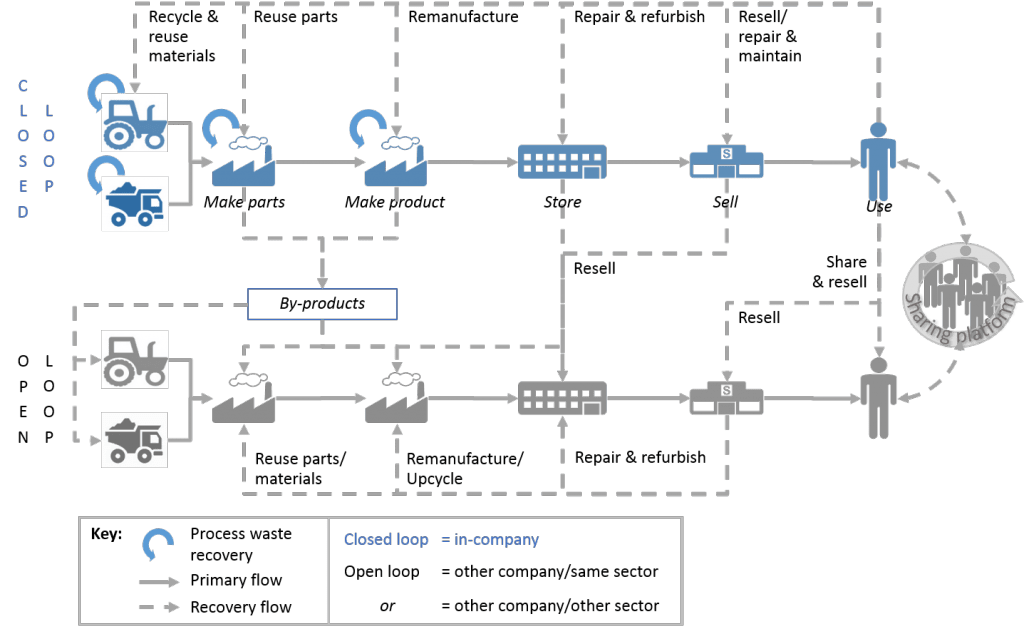

The circular economy gives us more effective, sustainable ways to rethink how we make and use everything. It aims to keep our resources circulating instead of ‘take, make, then waste’. Using circular systems means we could have enough, for all of us, forever, without destroying the planet we depend on.

Circular approaches keep products, components and materials in use for longer, and reuse them, so we get more value out of them. In a circular economy, all ‘waste’ becomes ‘food’. It can be a new input for another industrial process or compost, helping regenerate soils and biodiversity.

New materials, scientific advances and recent technology developments mean circular business can be more resilient, competitive, prosperous and sustainable.

“Businesses that work on the basis of circular principles are amongst the fastest growing in the economy”

Dr Martin R Stuchtey, McKinsey Center for Business and Environment,

from ‘Growth Within: A Circular Economy Vision for a Competitive Europe‘

Circular economy principles

There isn’t a universal definition of a circular economy – a recent study by Kircherr, Reike and Hekkert found 114 different definitions!

Most schools of thought share these circular principles:

- We design products and equipment to be durable and robust. Helping them stay in use for longer means a better lifetime cost for the user.

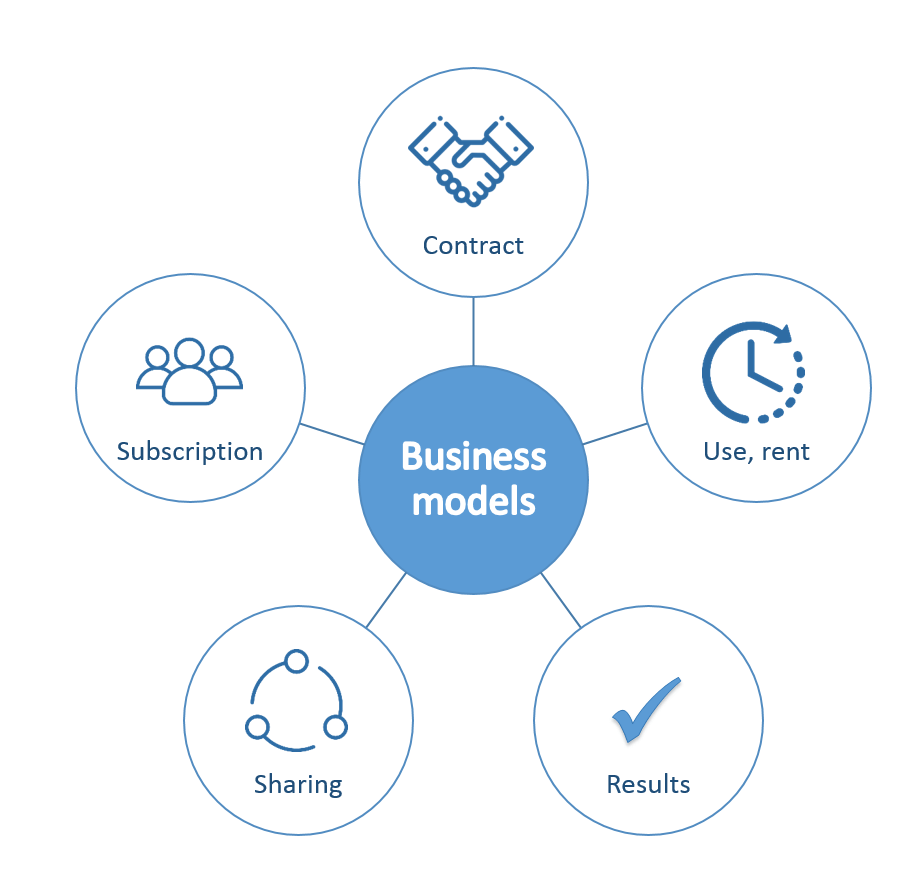

- Business models encourage the use of products and equipment, instead of ownership. Thse circular approaches also create markets for new services, including reuse, repair, remanufacturing and recovery of resources.

- We use safe, sustainable materials that are recycled or renewable.

- After we’ve used them, we recover the products, components and materials. This means they have value as a resource: perhaps for another industrial process, or as food for nature – compost! In other words, all waste = food.

Benefits for businesses – and our living planet

Circular economy strategies generate substantial savings, by reducing the materials we need, together with more efficient manufacturing and supply chains. These lead to lower levels of waste, pollution and GHG emissions… all better for society and nature.

Let’s look at the benefits in more detail, with some examples.

As a strategy for success, circular beats linear.

Durable, repairable products

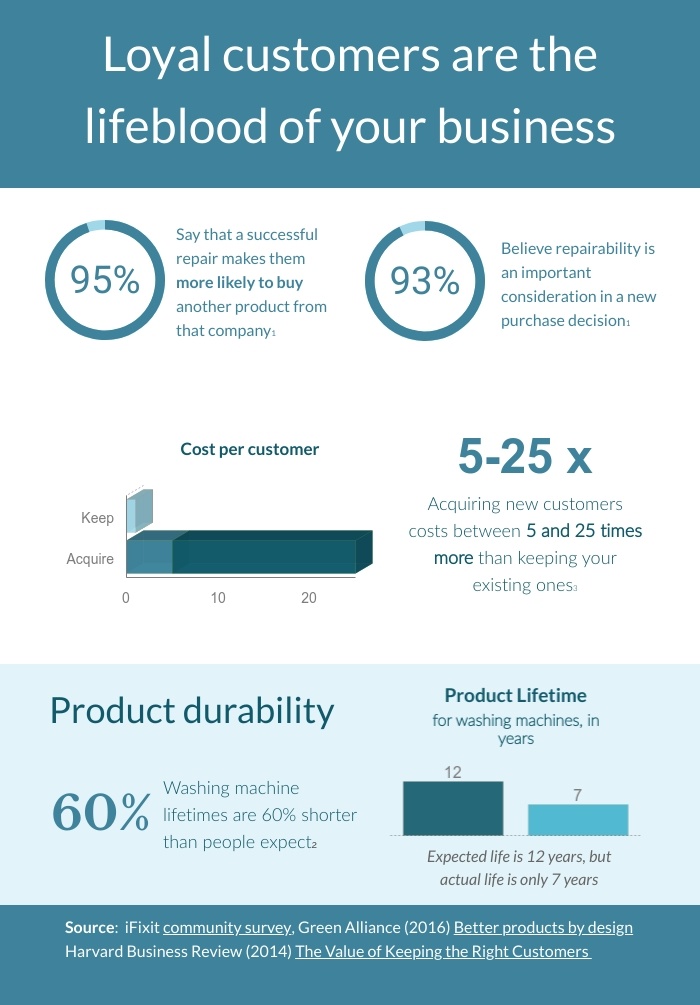

Many people consider reparability as important in deciding what to buy, according to survey by global repair community Ifixit, and 95 per cent of people say that a successful repair makes them more likely to buy more products from that company.

Does your product live up to customer expectations? In Europe, the average lifetime of a washing machine has fallen by a third between 2000 and 2010, with a machine now lasting only seven years, according to a report by Green Alliance. However, consumers expect these machines to last for 12 years. If your product doesn’t live up to expectations, how many people will choose a different brand next time? According to this research, the cost of acquiring a new customer is five to 25 times more expensive than retaining an existing one.

Companies can generate new profit streams from sales of spares and provision of repair services, to replace marketing and customer services costs. Loyal customers are likely to buy upgrades and other products from you. Furthermore, we spend less, both on new product development and disposal of obsolete products and parts.

Business models for access instead of ownership

Commercial models that support those more durable, shareable products enable both the products and the materials to stay ‘in the loop’ when the customer has finished using them.

Robust, repairable products are suitable for contracts, renting or sharing. In other words, it means more people use fewer products. This, in turn, reduces the resources, energy and emissions. A rented city bike might be in use for 12 hours a day. Compared to your personal bike, that you use perhaps once a week, that’s highly efficient.

Performance (pay by results) models offer ways to develop a win-win relationship with your customers and suppliers. Well-known examples are Rolls Royce aero-engines, and Philips now selling ‘pay per lux’ lighting services.

In textiles, Dutch aWEARness operates a closed-loop manufacturing process for its workwear production, with a recyclable polyester fabric. A leasing model retains ownership of the materials and customers pay for the performance of the clothes over an agreed number of years. Compared to standard cotton, it’s less polluting and more efficient. This system uses 95 per cent less water, 64 per cent less energy and produces 73 per cent fewer carbon emissions to make each garment. At the end of each ‘life’, the products are recycled back into new clothing, with no loss of quality

Waste = food

In production, we can save money by recovering offcuts and substandard parts for reuse, and by recycling water, energy and other inputs for reuse. We can also create valuable new by-products, from what we now consider as waste. Eliminating and reducing waste and pollution, through circular economy flows, is good for our living planet

At the end of use, we need to recover our products (including the components and materials) so we can recirculate them. Keeping them as intact as possible minimises the cost of making them fit for reuse. Those durable, repairable products may also be suitable for the user to re-sell, either themselves or through specialist retailers. One example is Watchfinder, a specialist marketplace for luxury watches, which was acquired in 2018 by Richemont, a Swiss luxury goods brand owner.

If the product needs more work to prepare for another cycle of use, then we might need to refurbish or remanufacture it. Designing the product with this in mind improves the profitability of remaking and resale.

In the US, remanufactured products have the same warranty as a new one, giving the buyer confidence. More companies are developing highly profitable remanufacturing solutions, with Dell, Caterpillar and Cummins as big-brand examples.

Remanufacturing can open up new markets. Are there areas where your brand is known for its reliability, but is expensive compared to lower-quality competitors? A great example is

Recycling: the final frontier!

Because it uses the most energy and resources, recycling should be our last strategy. A report by Green Alliance found that for mobile phones, the value of the recyclate is only 0.24 per cent of the original product value. In contrast, a reused iPhone retains almost half its original value.

How can we redesign our wasteful, polluting, linear economy? What could you do to rethink waste and create value?

Are you losing customers because you’re not meeting their expectations for durability or performance? Are they frustrated by the waste when they’ve finished using it? Perhaps they’re choosing a cheaper competitor brand?

Getting started with circular approaches helps create high-quality products that your customers will love – and loyal customers make a healthy business ecosystem (and a healthy planet)!

How can you use the circular economy to do more good for our living planet?

“There is no business to be done on a dead planet”

David Brower

An earlier version of this