The circular economy creates and captures new value for businesses, and adds extra dimensions to supply chains. It’s gaining momentum as a critical tool for future-fit businesses. Nike, M&S, Renault and many others are developing circular products and services. Circular start-ups are thriving. My book explores the drivers and benefits of the circular economy in detail, with wide-ranging examples and digs deep into the implications for the supply chain.

The circular economy creates and captures new value for businesses, and adds extra dimensions to supply chains. It’s gaining momentum as a critical tool for future-fit businesses. Nike, M&S, Renault and many others are developing circular products and services. Circular start-ups are thriving. My book explores the drivers and benefits of the circular economy in detail, with wide-ranging examples and digs deep into the implications for the supply chain.

Here’s how to get started.

Turbulence ahead

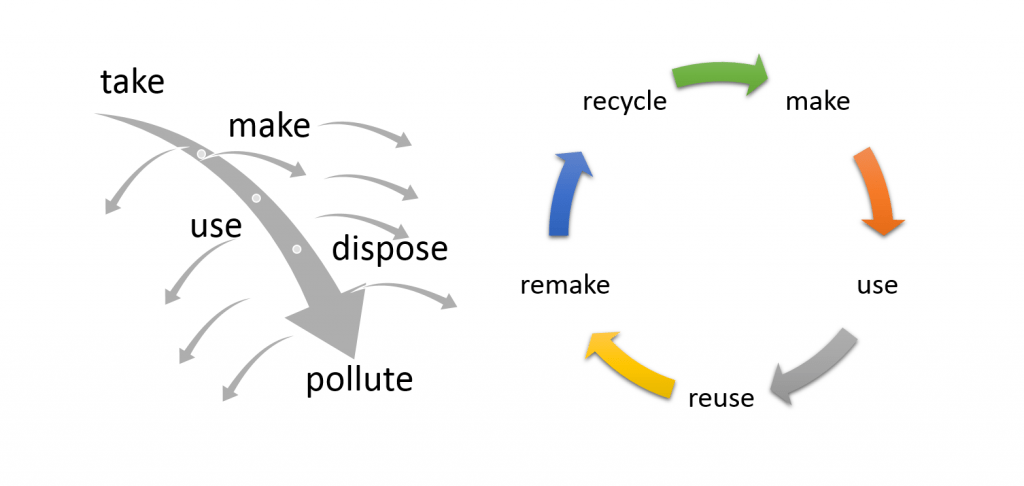

After a turbulent 2016, it feels like our world is changing ever faster: ‘megatrends’ include urbanisation, a redefined world order, rising inequality and political upheaval. Predictions include 3 billion new consumers set to enter the market by 2030 and the internet-connected population doubling to 5 billion in the next 5 years – fantastic business opportunities. Disruptors, like Airbnb, Spotify, Uber and others, scale up rapidly, displacing established brands and entire sectors. Amazon has even filed a patent for aerial warehouses. Most businesses operate on ‘throughput’ principles (see the footnote on issues of the linear economy): take some materials, make a product, sell it and work out how to sell the next one. But this approach shackles growth for many businesses as demand for resources, land and water outstrips supply.

A circular revolution

So, how do you survive and thrive in these challenging conditions? Across the globe, in every sector, start-ups and big businesses are exploring the ‘systems thinking’ approaches of the circular economy. Some businesses are trying to disrupt from the inside: how would a new competitor design your business? How would a disruptor innovate products and services, decouple resources from profit, build brand loyalty and create resilient, adaptive organisations?

OK, give me the lowdown on the circular economy

Instead of leaking value by discarding products and materials after use, the circular economy redesigns products, processes, supply chains and business models to yield more value. Creating durable products, and recovering products and materials at end of use, enables reuse, repair, remanufacture and recycling. Simple examples include:

- Making orange juice: the ‘waste’ becomes by-products, with pectin, pulp and zest for food manufacture and essential oils for pharmaceuticals and cosmetics.

- Commercial photocopiers aren’t sold now; photocopying is a service with efficient repair networks plus refurbishment and remanufacture to enable second and third ‘lives’ for each machine.

Circular economy approaches regenerate ecosystems to better support human health and well-being. By converting ‘take-make-waste’ into ‘value loops’, creating more from less, they decouple resource use from value creation.

From leaky to loopy – extra dimensions for the supply chain

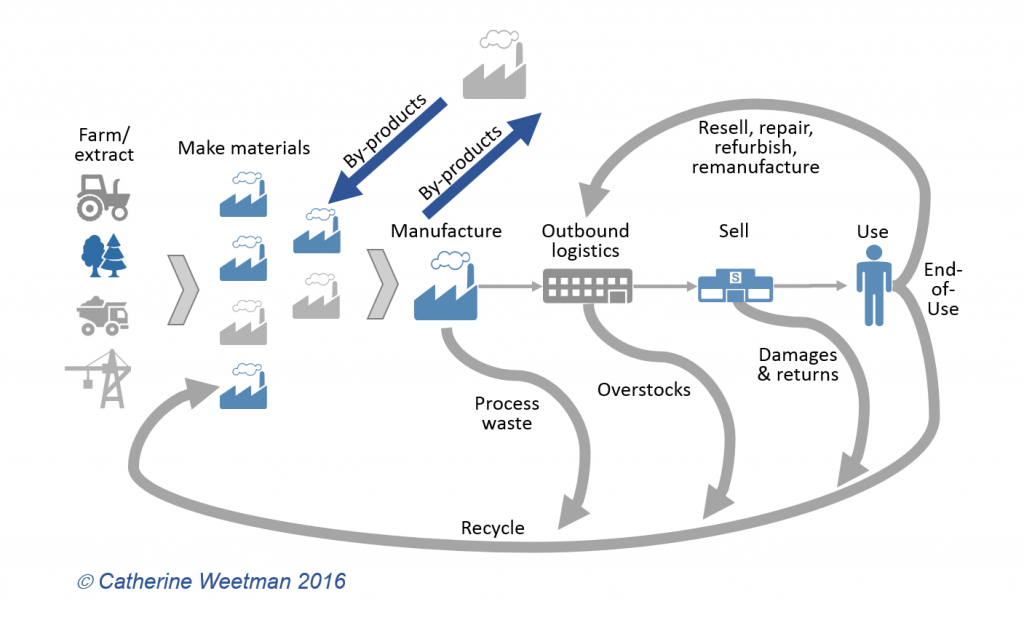

Circular economy terminology often categorises materials into two groups.

- Biological nutrients – food, fibres, timber – should be sustainable, renewed to meet or exceed the rate of extraction.

- Technical nutrients – metals, minerals, fossil fuels – should cycle infinitely. Product design can support effective separation at end of use for efficient recycling.

This over-simplifies the choices, but starts to encourage a different mind-set, focussing on material choices and the ease of separation at end-of-use. Another lens to use is ‘100% yield’ rather than ‘zero waste’. Here businesses create new value from by-products and co-products and look for ways to recover and reuse energy and water inputs. ‘Green chemistry’ and bio-refineries are finding new ways to extract valuable bio-chemicals from waste streams, providing inputs for pharmaceuticals, food and cosmetics before using the residual materials to create energy… take a look at how British Sugar has created new value streams from sugar beet.

When supply chains become multi-dimensional: new flows and formats, service networks, more ‘touch-points’, recovery loops for products and materials – they are ‘loopy’ instead of leaky. Cycling materials and protecting their value (ready for resale, repair, remanufacturing or recycling) means re-thinking reverse supply chains and packaging design – not just Reverse Logistics 2.0!

Procurement processes and contracts should focus on outcomes, enabling a ‘win-win’ approach for suppliers and buyers. Can you swap finite materials for recycled or renewable (and ensure biomaterials don’t displace a food crop or contribute to deforestation)? Do you purchase something that is recyclable, but not recycled? Can you change that?

New by-products could be chemicals, gases or bulk solids, with diverse handling and transport needs that contrast with the mainstream products.

New partners will emerge – perhaps supplying their by-products or high-quality recyclate to you as specialist repair and remanufacturing providers, or in eco-parks with symbiotic flows of materials meaning ‘waste’ from one company becomes a ‘nutrient’ for a neighbour.

How do I get started?

Talk about circular approaches with your colleagues across the business – what’s already happening in your sector or in other supply chains? There are likely to be a few ‘quick wins’ you can investigate, so you can begin the circular journey with little disruption and risk.

- Prioritise: are there some high-risk products or materials you buy, with volatile prices, toxic or scarce materials that you could replace with something safe and secure? Where are the biggest opportunities for value – could you recover your own resources, or create value from a new by-product? Could you design something to be more easily disassembled for repair or recycling? Could you swap from buying a product to contracting for service or performance, such as ‘tyres by the mile’?

- Work with suppliers to share your vision, scan for ideas and specify the goal (not the ‘how to’). Help your suppliers innovate for a ‘win-win’ outcome.

- Use learnings from those quick wins, build your experience and gain buy-in from other stakeholders.

- Invest the learnings and benefits in the next projects – perhaps bigger scale or requiring more disruption to existing processes

- Tell the story to suppliers and consumers – engage a wider group of stakeholders and create momentum

Strategies and initiatives will evolve and improve, as you build on lessons learned (read my book for more ideas, implications and innovation tips). You could choose simple examples to use yourself: a repairable Fairphone, 3D printed sunglasses, or some recycled pens. You don’t need to create a completely closed loop product or service, or reinvent your entire supply chain – just start somewhere!

Strategies and initiatives will evolve and improve, as you build on lessons learned (read my book for more ideas, implications and innovation tips). You could choose simple examples to use yourself: a repairable Fairphone, 3D printed sunglasses, or some recycled pens. You don’t need to create a completely closed loop product or service, or reinvent your entire supply chain – just start somewhere!

Footnote: the value leakage in our linear economy

Marketing aims to create a dissatisfaction with what we have now, encouraging us to buy more ‘stuff’, or replace what we have with something ‘better’. We could describe our current economy as a ‘waste’ system. It is woefully inefficient, using ‘subtractive’ manufacturing processes: start with a lump of something and knock bits off to make the shape needed. At end of use materials are sent for landfill, incineration or exported (often to where materials can be recovered without onerous safety regulations), allowing value to leak out of the system. For food, one-third is wasted between farm and fork; only around 14% of plastic packaging is even collected for recycling; a record 53.6 million metric tonnes of electronic waste (e-waste) was generated worldwide in 2019, up 21 percent in just five years, according to the UN’s Global E-waste Monitor 2020. Harmful ‘externalities’ from farming, extraction and manufacture – toxic waste, pollution of air, atmosphere, water and soil – are destroying the living systems we depend on – pressuring the earth systems and biodiversity ‘services’ we depend on, like never before. We make more ‘stuff’ to replace these degraded natural systems, or suffer the consequences through disease, healthcare costs and productivity leakages. [back to main text]

Versions of this article were first published by Kogan Page in February 2017.